Maintain

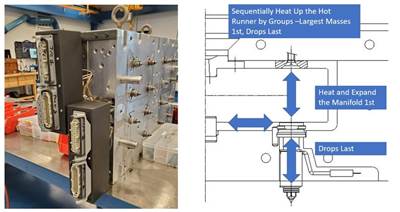

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreHot Tip Sprue Cleaner Melts Obstructive Plastic

The hand-held tool from Globeius Inc. brings plugged hot runner sprues and nozzle tips back to life quickly and safely, sometimes without needing to remove the mold from the press.

Read MoreDual-Mode Metrology Scanner for Accurate Mold Measuring

The highly ergonomic and compact FreeScan Combo from Shining 3D adopts metrology-grade accuracy, fine scanning and high precision for inspection and reverse engineering.

Read MoreVIDEO: Hot Runner Maintenance Tips

Scott Clark, Hot Runner Business Manager for Husky Technologies, breaks down maintenance practices for hot runner systems.

WatchNoncontact Laser Scanner Enhanced for Mold Inspection Suitability

Wireless Nikon Metrology LC15Dx inspection tool features increased resolution and accuracy of data acquisition for continuous feedback of metrology information, further enhancing its versatility and efficiency.

Read MoreMold Care, 3D Scanner Best Practices, the State of Maintenance & More Most-Viewed April Content

April held a little bit of everything for MoldMaking Technology. From mold care and maintenance to 3D scanner and printing best practices, take a look at what might have missed your radar.

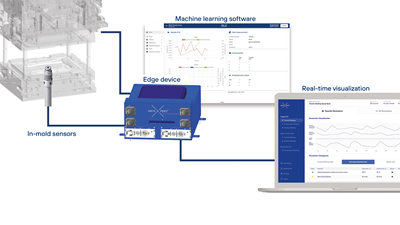

Read MoreIn-Mold Sensor Technology Assists With Sustainability Goals

SensXpert Digital Mold from Netzsch Process Intelligence is intended to help the plastics industry reach governmental and environmental sustainability goals.

Read MorePrecision Coating Acquires Providence Texture

Providence Texture brings innovative femtosecond and nanosecond five-axis laser processing solutions to functional and aesthetic surfaces, in addition to nanotexturing, marking and micromachining.

Read MoreMMT Chats: SPE MTD 2023 Mold Repair Person of the Year

MoldMaking Technology Editorial Director Christina Fuges sits down with the newly named SPE Mold Technologies Division 2023 Mold Repair Person of the Year to learn about his passion for mold repair. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchMold Lifting Rings Offer Efficient Mold and Die Management

PCS Company's Codipro Mold Lifting Rings are said to provide more efficient material handling and moving of molds and dies in any shop or molding facility.

Read More

.jpg;maxWidth=300;quality=90)