At MoldMaking Technology, our team takes great pride in our commitment to delivering an array of invaluable insights and practical advice tailored specifically for our audience within the industry. We bring this insight to our audience via our “Tips” column, a one-page article that is published monthly in MoldMaking Technology magazine as well as on our website that shares expertise and “lessons learned” with fellow mold builders, using real-world examples and supporting data.

Here are our top five most-viewed tips of 2023 based on Google Analytics.

Welcome! You’ve unlocked premium content.

5. How to Address the Mold Engineering Skills Gap

Four ways to equip mold engineers with the necessary knowledge to tackle the skilled workforce crisis.

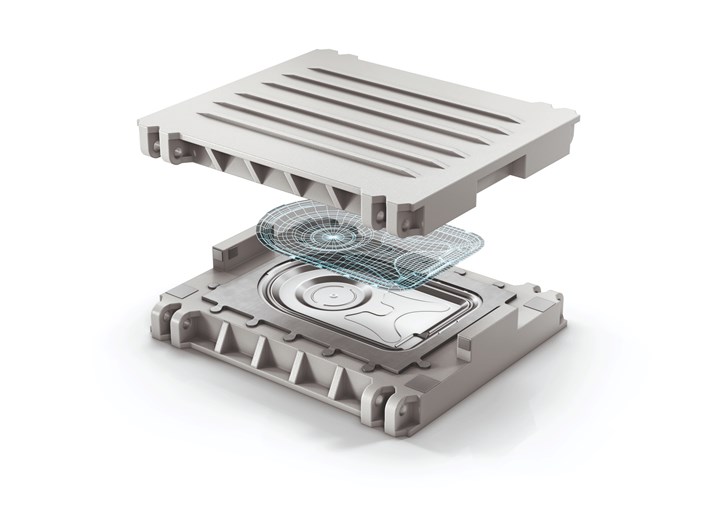

4. CNC or 3D Printing: 5 Factors to Consider

Accuracy, time, cost, nimbleness and application considerations help to determine if a shop should use CNC machining or 3D printing.

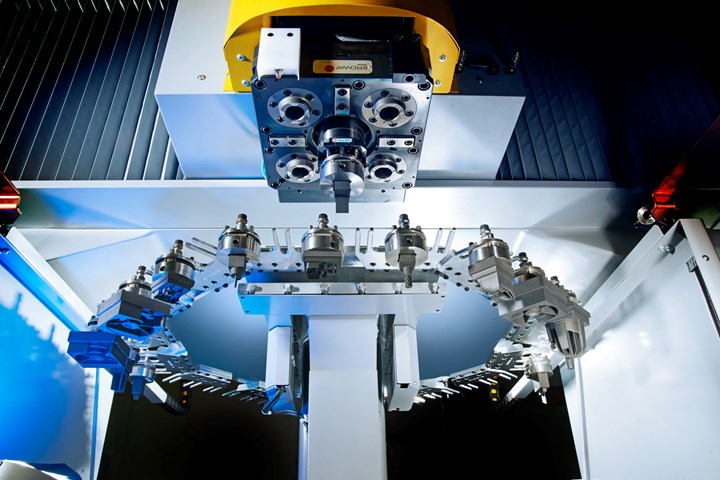

Speed, machine design, software, artificial intelligence and automation help maximize sinker EDM productivity.

2. Three Ways to Accurately Machine Hardened Mold Materials

Three cutting tool design considerations to improve process reliability and cost efficiency when deep-hole drilling molds.

1. How to Polish Ribs for Proper Part Release

Using the right tools and abrasives is essential to polish a mold to the required final finish.

Photo Credit: D.W. Sales

Check out our "Tips" page for more insights from moldmaking professionals

Related Content

-

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

-

Confronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

-

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.