Design & Mfg. Software

Injection Molding Analysis Ahead of Tool Production Removes Guesswork From Mold Manufacture

Patented injection molding analysis ahead of tool production, ensures that a number of components in a water powered rock drill are manufactured to the degree of absolute precision required by mining operations around the world.

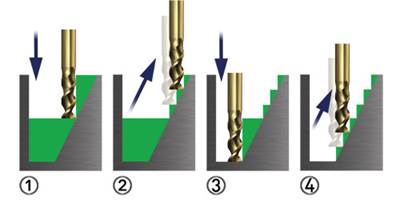

Read MoreHow to Lengthen Tool Life with CAM Software Moves

Long tool life is a combination of three elements: the tooling used the way it’s designed to be used; the holder to contain that tool as rigidly as possible; and how the programming software is applied

Read MoreSoftware Streamlines Complex CAD Design

Understanding its success in the market, Caprock kept its focus on the design process and, in 2011, decided to upgrade its CAD tools to Solid Edge® software from Siemens PLM Software (Plano, TX).

Read MoreTaking Toolpath Creation out of the CAD Office

The VISI suite of CAD/CAM software was instrumental in designing the head configurations, handle and 3-D tooling, along with the CNC toolpaths for a the collapsible shovel.

Read MoreReduce Tooling Costs and Time with Laser Scanning

Aircraft Technologies, Inc. (San Antonio, TX)—a leading manufacturer of toilets for corporate jets—saved $20,000 and four weeks in reduced tooling costs/time for a new model by utilizing NVision’s (Coppell, TX) laser scanning and engineering services.

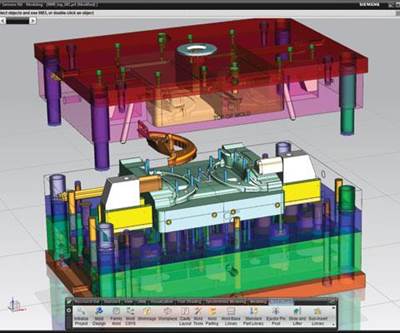

Read MoreFive Benefits of Integrated CAD/CAM

Integrated CAD/CAM software that combines CAD, CAM, electrode design and CMM programming capabilities in one system can save you time and effort in the following five ways:

Read MoreTaking Streamlining to the Next Level

Based in Rochester, NY, Aluminum Injection Mold Company (AIM; Rochester, NY) is an industry pioneer in providing creative production aluminum tooling solutions to a wide range of markets including automotive, medical, computer / business machines, telecommunications and consumer products since 1985.

Read More

.jpg;maxWidth=300;quality=90)