Cutting Tools

High-Feed Milling Insert Addition Adds to Mold Machining Optimization

IMTS 2024: New 6-millimeter inserts for the Iscar Mill-4-Feed enhances free cutting action capabilities for extreme material removal rates.

Read MoreHigh-Feed Cutting Tools Offer Longer Reach, Stable Cut

IMTS 2024: Horn USA Inc. offers tool systems, such as its DAH cutters, designed for high-productivity, cost-efficient machining processes.

Read MoreSix-Flute End Mill Refines Features for Mold Cutting

IMTS 2024: Ceratizit’s six-flute end mill, designed for high toughness with equally high hardness, is engineered for titanium, superalloys and even tool steels.

Read MoreTechnology Review and Sourcing Guide 2024: Cutting Tools

Mold cutting tools are used on machine tools to cut metal and are one component of the overall mold machining process to consider when looking to improve speeds, feeds, wear and surface finish. Access this exclusive, online-only content, including a suppliers list, cutting tool products and more.

Read MoreCBN End Mill Series Cultivated for Ultra-Precision Molds Manufacture

IMTS 2024: In response to mold building customer needs, Towa’s cutting tool lineup targets precision and durabilty features required for these applications.

Read MoreCoating Technology Enables Tough Mold and Die Steel Machining

Millstar, a part of Cole Tooling Systems, presents a multi-layer hybrid nanocoating for cutting tools that provide key benefits for increased efficiency in any machining operation.

Read MoreHow to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

Read MoreThread Mill Designed for Core Hole Creation, Chamfering

The Walter USA solid carbide TC685 orbital drill/thread mill is for hard machining of the core hole and thread in one operation.

Read MoreIngersoll Introduces July 17th Die and Mold Seminar

Ingersoll is offering a mold and die seminar to place focus on proper tool selection and the application of the latest cutting tool technologies.

Read MoreButton Insert Available for Copy Milling Cutter

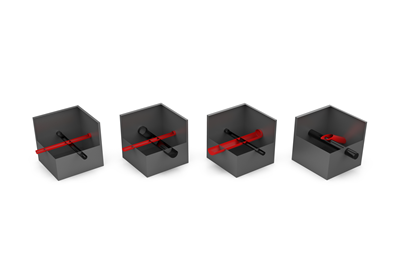

The Walter Tiger·tec Gold WMP45G round insert, available in several diameters and geometries, features high pocket stability to cost-effectively achieve complex forms.

Read More

.png;maxWidth=300;quality=90)