Cutting Tools

Integrated Manufacturing System Connects Process Platforms, Streamlines Cutting Tool Production

ANCA’s AIMS uses smart automation and IT integration to connect tool production processes and systems for maximized productivity and end-to-end tool manufacturing.

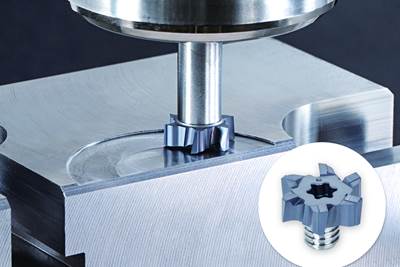

WatchFace Milling Cutter for Maximum Reliability

Walter’s Xtra-tec XT M5012 face milling cutter with small indexable inserts and large depth of cut delivers versatility and accessibility.

Read MoreGWS Tool Group Acquires Taurus Tool & Engineering

The acquisition enhances the GWS product portfolio and capabilities in the area of custom HSS tooling and custom thread-on modular tooling, while adding additional capacity for complex carbide hole making and milling tools.

Read MoreHigh-Performance Drill Targets Low Cutting Speeds For Unstable Environments

Big Kaiser’s Nirox high-performance drill from Sphinx boasts a TiAlSiN-based coating for enhanced chip and coolant evacuation in difficult-to-machine and adhesive materials.

Read MoreHigh-Speed Spindle Series Harnesses High Coolant Pressures for Small Cutters

Tungaloy launches the iteration of its HPC SpinJet line, an easily adaptable tool which uses coolant pressures of up to 70 bar (1,015 psi).

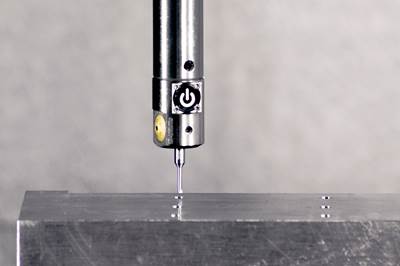

Read MoreDigital Boring Head Program Offers Smaller Sizes

Head sizes down to the CKB1 modular tooling connection size are now offered by Big Kaiser. They will feature the same boring ranges and accept the same accessory products as their standard analog counterparts.

Read MoreVFM Milling Head Enables Face Milling with Exchangeable-Head End Mills

The new addition to the Tungaloy TungMeister series of exchangeable-head end mill systems is designed to reduce a significant amount of tool changeover time for additional efficiency.

Read MoreJanuary Technology Roundup: Cutting Tools, Miscellaneous

MMT provides a brief glimpse at the cutting tools and miscellaneous products/services highlighted in the January 2021 print and digital issue.

Read MoreSynchronized Tap Adaptor Increases Tool Longevity

The Walter AB735 synchronized threading insert compensates for axial movement, increasing tool life and lowering inventory costs.

Read MoreRough Boring Insert Holder Excels in Compatibility and Speed

Allied Machine and Engineering’s new VolCut insert holder for rough boring excels at removing large amounts of material for large-diameter applications.

Read More

.png;maxWidth=300;quality=90)