Let’s start off the new calendar year right with MoldMaking Technology’s monthly product/service roundup. The highlighted companies and pieces found below provide a brief glimpse into what you might see in MMT’s January 2021 print issue (find all archived and recent digital issue versions here on the 1st of each new month). January’s print focus was cutting tools and miscellaneous.

Never seen some of these before? We publish new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar for a more streamlined approach. Follow each title link for the full product post.

Click here for November and December’s technology roundup.

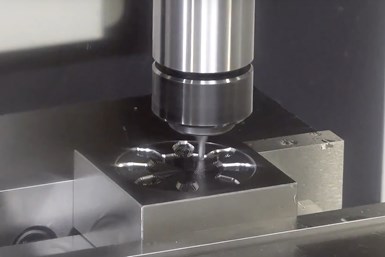

Horn USA highlights its expanded tool range for high polish milling. The monocrystalline, diamond-tipped (MCD) ball nose end mills, intended for machining non-ferrous materials in the tool and moldmaking industries, save on polishing processes when producing free-form surfaces.

Horn offers the expanded portfolio of MCD ball nose end mills from stock. Diameters of 6 mm, 8 mm, 10 mm, 12 mm and 16 mm allow a broader range of applications to be covered.

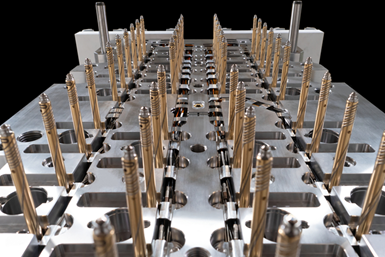

Adding to Husky Injection Molding Systems’ Ultra Helix Valve Gate nozzle lineup, the Ultra Helix 250 T2’s advanced design minimizes wear, provides high gate quality and longevity and was specifically developed to extend the benefits of the Ultra Helix technology to jobs for small part weights and difficult-to-access gate locations.

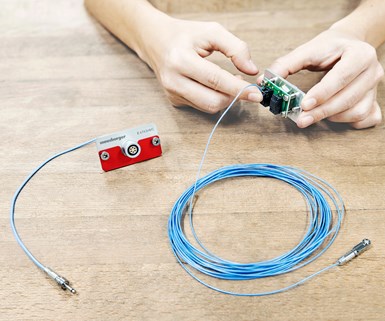

With Schunk’s iTENDO sensory toolholder, it will be possible to monitor machining processes in high resolution at the tool, and to control cutting parameters in real time. The required acceleration sensor and electronics are integrated into the toolholder without affecting its interfering contour and other characteristics.

According to Schunk, the iTENDO seamlessly records the metal cutting process, monitors previously defined exact limit values and, in the event of irregularities, enables real-time adaptive control of the speed of rotation and feed rate, among other measures.

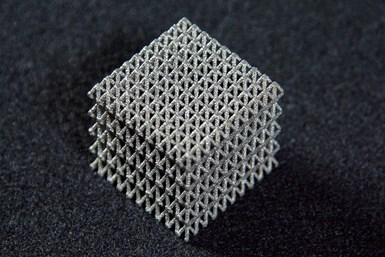

The release of Siemens Digital Industries Software’s Parasolid open software technology for geometric modeling is said to enable the solving of the most difficult technical challenges and improves upon 3D printing and scanning-based workflow with new tools for Convergent Modeling and lattice structures.

Tungaloy has expanded its DrillForce-Meister exchangeable head drill series by adding SMF-style flat head drill tips, which tackle large diameter counterboring challenges, and is suitable for parts and materials found in a wide range of industries.

The SMF-style flat head drill tips are designed to efficiently open large diameter holes ranging from 20.0 mm to 40.0 mm (0.787″ – 1.575″) at a lower cost. Further, the exchangeable drill tip feature eliminates the need for regrinding and recoating—as is the case with solid carbide drills—and reduces the amount of tool float inventory kept to avoid machine downtime, minimizing the overall cost per hole in high-volume production lines.

Contending that it carries the world’s widest range of mold counting and monitoring products, Progressive Components (Wauconda, Illinois) has recently expanded the line to include CounterViews, along with new accessories.

As an industry exclusive, the CounterView cycle counter is now available in both left- and right-hand orientations to allow mounting on either mold half, enabling easy viewing while the mold is in the press.

OSG has released a range of new end mill products, including the HY-PRO CARB VGM end mills and the A Brand AE-H advanced performance carbide end mill.

The HY-PRO CARB VGM variable end mill is a series of variable geometry end for dynamic milling, ideal in steel and stainless steel.

The A Brand AE-H advanced performance carbide end mill for high hardness steel are available in three styles to cover a wide range of applications.

Emuge Corp.’s micro milling/drilling chucks, like the company’s micro end mills, are ideal for a wide range of die and mold, and medical applications.

The chucks feature a slim design for hard-to-access areas, as well as high gripping torque and accuracy. Part of the high precision/performance Emuge FPC Mill/Drill Chucks line, this product is said to provide unprecedented rigidity, vibration dampening, concentricity, machining speed and tool life versus conventional chuck technologies for milling and drilling applications.

In addition to its existing range of cavity pressure sensors for plastic injection molding process monitoring, Meusburger now offers two charge transfer versions, the single wire E 6760 and the E 6757 mini coaxial cables, as well as matching multi-channel connectors for optimal process quality and increased part sustainability.

With a cable wire diameter of 1.2 mm, the single wire cable is ideal for molds with limited space. The E 6757 coaxial cable is characterized by optimal shielding against external signals due to its steel sheath, making it ideal for molds with a high number of electrical components.

The challenge when cutting steels greater than 60 HRC and moderate steels with abrasive properties lies with the cutting tool used in the process, says U.S. Union Tool Inc. (Anaheim, California). To address this challenge, the company introduces the HGB/HGLB Ball nose series, designed specifically for these types of applications, meeting the rigors of cutting hardened/abrasive steels in the 59-70 HRC range.

United Grinding North America’s Blohm PROFIMAT MC high-performance heavy-duty traveling-column grinding center is said to offer the capabilities modern production environments require for various industries and applications. Measuring 94.488" (2,400 mm) wide, the 5-axis, space-saving machine includes an automatic tool changer with up to 24 tools and offers multiple spindle configurations, including an optional horizontal spindle or a stationary or NC-swiveling vertical spindle.

Walter’s new versatile Xtreme Evo DC160 Advance solid carbide drill is said to deliver exceptional productivity in a wide variety of materials, and a broad range of applications, which include the mold and die, energy, automotive, and general metalworking sectors.

Available in a variety of dimensions, now up to 30 x Dc and in diameters from 0.125-0.75 (3-25 mm), the DC160 Advance solid carbide drill features grades WJ30ET (full coating) for universal usage up to 8 x Dc and WJ30EU (tip coating) for 12 x DC up to 30 x Dc.

Precision Twist Drill (PTD), Union Butterfield and Dormer are just a few brands representing cutting tools and accessories that Dormer Pramet has created for MRO professionals. Easy to select and comprehensive for MRO needs, Dormer Pramet has identified drills, taps, dies, reamers, end mills and rotary burrs that will deliver reliable and cost-effective results in portable and machine applications and in a wide range of operating conditions for various materials.

Sunnen Products Company offers a series of drill heads, inserts and pads that are directly interchangeable with Sandvik deep-hole drilling tools. The new line, Sunnen DirectDex, features BTA/STS (single tube system) and DTS/Ejector (double tube system) style deep-hole drilling tools designed to produce a low cost-per-bore with consistent performance. The series directly corresponds to the previously available line of Sandvik drill heads, inserts and guide pads, with additional product series set to be released soon.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)