Business Strategy

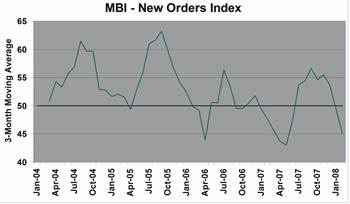

Economic Growth Slows; Expectations Positive 41.7 Total Mold Business Index for February 2008

Overall economic growth in the U.S. is sputtering so far this year, and this is constraining demand for new molds in the first quarter of 2008

Read MoreHow to Design High Cavitation Tooling

Today's sophisticated dispensing closure tooling represents a significant capital investment and requires skillful selection of a mold supplier. This tooling is highly complex and requires a higher level of precision due to multiple product design functional requirements. Living hinges, linerless bottle plug seals, product shipping seals, dispensing orifices, internal or external threads, and mating component fits have a great impact on how the tool is designed.

Read MoreDynamic Tool & Design, Inc.: Automatically Inclined

By fully integrating automation into its process, this shop services its customers from part design to sampling—and everything in between.

Read MoreJust Let’r Leak

How a typical 20-press, West Coast molding facility investigated the downtime impact of water leaks in their plant. Always looking for an edge, and a way to reduce costs, they put together a year-end defect costs summary to use as a guide in the toolroom, so they could aggressively pursue their goal of reducing unscheduled mold stops.

Read MoreStarting with a Clear Road Map

I am second generation in the moldmaking industry. My father was a moldmaker and I became a mold designer. I started as a design apprentice in the early 70s

Read MoreWill You Be Competitive?

Last month, I asked in this column, “Are You Competitive?” I covered issues that you can use to measure if you are really competitive in the markets you serve, and if your business appears competitive to your customers and prospects— today. That column was intended to help focus on survival and near-term growth strategies. Among the questions I suggested you ask yourselves was, “Who Are Your Customers?”

Read MoreStrategic Challenges of the Past Decade

What have been the most significant challenges for the Society of Plastics Engineers, Mold Making & Mold Design Division membership in the past decade? The answer—while not all that surprising—remains a constant that the industry has experienced throughout the history of the market segment.

Read MoreTop 10 List

What technologies were instrumental in changing mold manufacturing in the past 10 years?

Read MoreStaying Strong

As a result of the challenging times the moldmaking industry has faced during the past 10 years, networking has become a means to staying strong. Establishing and maintaining relationships with people in your industry is key to survival and growth.

Read MoreSights and Sounds of Show Week

it has always been our mission to bring you the experts and stories that will help you learn about the technology and business strategies for improving your’s shop efficiency, productivity and profitability.

Read More