April showers brought a little bit of everything to MoldMaking Technology. Take a look at the evolution of 3D printing in moldmaking, find out if your toolroom is reactive or proactive when it comes to maintenance, learn more about Helm Tool and more.

10. Editorial Advisory Board 2023-2026: Meet New Board Member Adam Nartker, Diversified Technologies International

The 2023-2026 version of MoldMaking Technology’s EAB features a new crew of industry professionals. Meet Adam Nartker.

Adam Nartker, business development manager of plastic injection molds for Diversified Technologies International (DTI) in Livonia, Michigan, is one of MMT's new editorial advisory board members.Photo Credit: Adam Nartker

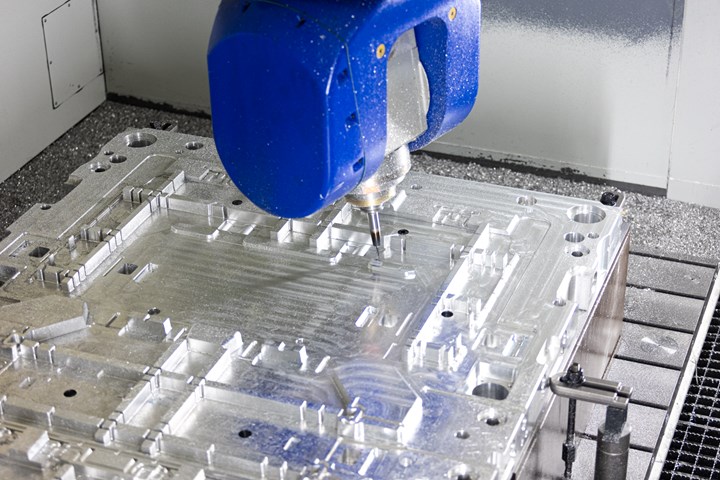

9. Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Innovation, leading technology, craftmanship and expert employees are key to Helm Tool’s 45-plus year history. Photo Credit: Creative Technology Corp.Photo Credit: Creative Technology Corp.

8. VIDEO: Insights and Best Practices for Mold Care

Slide Products President Michael Muth shares the products and practices he believes have helped the moldmaking industry the most when it comes to caring for molds.

7. Three 3D Scanner Investment Considerations

Mold builders taking advantage of laser and software advancements for portable 3D measurement tools can reduce inspection and measurement times.

6. MMT Chats: SPE MTD 2023 Mold Maker of the Year

MoldMaking Technology Editorial Director Christina Fuges takes the opportunity to sit down with the newly named SPE Mold Technologies Division 2023 Mold Maker of the Year to learn about his lifelong career in moldmaking. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

5. Pennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

4. 5 Sinker EDM Advancements

Speed, machine design, software, artificial intelligence and automation help maximize sinker EDM productivity.

Photo Credit: Photo Credit: MC Machinery Systems

3. The State of Maintenance: Where Are You?

Photo Credit: MoldTrax LLC

New products, equipment and software are beneficial to mold maintenance, but they do not change the fundamental way a repair technician performs the job if the culture remains reactive. Is your toolroom reactive or proactive?

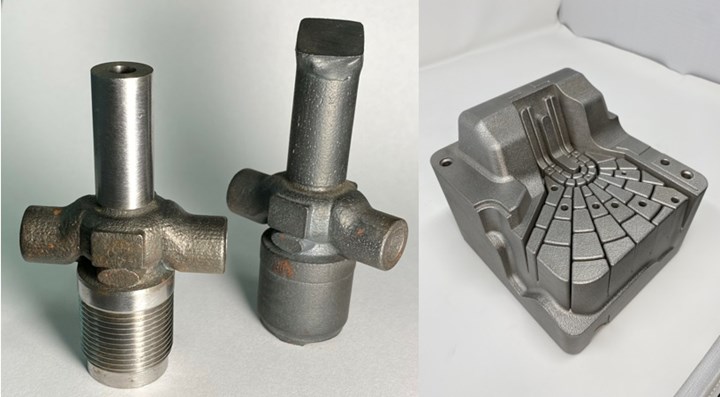

2. A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

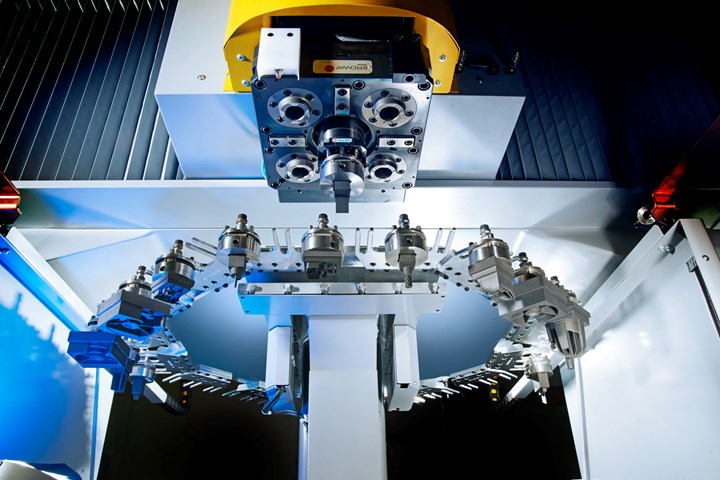

1. True Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Photo Credit: CDM Tool & Mfg. Co.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.jpg;maxWidth=300;quality=90)