Workholding

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

WatchZero-Point Workholding Systems Facilitate Workpiece Clamping Ease

IMTS 2024: HWR Workholding USA highlights its full line of SolidLine and InoLine workholding products with recent and existing solutions for turning and milling applications.

Read MoreCNC Platform Creates Adaptable Interface for Workholding

IMTS 2024: Features such as advanced collision protection and greater operational functionality make Heidenhain’s TNC7 CNC control platform critical for mold builders, who often face multi-surface machining.

WatchToolholding, Metrology Systems Increase Accuracy and Efficiency

IMTS 2024: Rego-Fix introduces automated tool clamping units, spindle drawbar force testing tool for increased efficiency, measurement accuracy and machining capabilities.

Read MoreTool Balancing Equipment Ensures Consistent Moldmaking Results

Zoller enables balanced toolholders, tool assemblies and grinding wheels using its »toolBalancer« series, providing high-quality surface finishes and extended surface life to spindles and cutting tools.

Read MoreShrink-Fit Machine Features Integrated Cooling

Power Clamp Air i4.0 Eco by Haimer USA provides smooth and clean cooling of all kinds of toolholders or collets by air, without dirt and water residue.

Read MoreToolholder Solutions for Moldmaking

MMC Collet Chucks, SK Collet Chucks and Shrink Fit Toolholders presented by Lyndex-Nikken are designed for accuracy to meet the demands of machining molds.

Read MoreHydro Chuck Toolholder Promises Precision When Heavy Milling

Precision cutting tool solutions manufacturer NT Tool presents Hydro Chuck Omega, designed to eliminate the common issues of chatter, deflection and pullout.

WatchFace Mill Holder With Damping Vibration Control Supports Far-Reaching Operations

Big Kaiser, a member of the Big Daishowa Group, offers the new SDF57 arbor-style face mill holders, what it claims is the largest and longest milling tool, which could have important benefits for moldmakers.

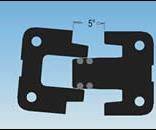

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read More