Validation Software Enables Efficient Translation of CAD/CAM Data

Verisurf CAD/CAM, now providing access to Kubotek Kosmos Validate software, is designed to ensure data integrity and enable users to perform metrology workflows in a seamless CAD environment.

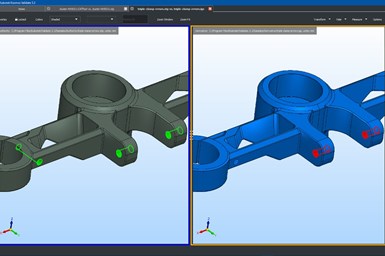

Verisurf Software Inc. has announced that its integrated CAD/CAM translation and validation software, Validate, now includes direct access to an enhanced standalone version of Kubotek Kosmos Validate software. The two companies have reportedly worked together since 2011 and created the Verisurf Validate module that works within Verisurf and supports CAD/CAM translation validation for customers needing to meet Boeing Standard D6-51991. Kubotek Kosmos maintains an expanded version of the software with added features and bidirectional compatibility between all popular CAD/CAM software programs and file transfer protocols, which is now accessible directly to Verisurf Validate customers.

3D model-based definition (MBD) enables manufacturers to reduce errors and avoid manual data re-entry introduced by the traditional drawing-based communication processes. In a MBD process, the original 3D model is the authority dataset to which all manufacturing is verified against. To ensure critical data is not lost or altered as it moves into specialized manufacturing and quality verification software, OEM quality assurance systems commonly require suppliers to document validation of all translations. This is typically part of established product acceptance software (PAS) requirements put in place by OEMs.

Efficient, accurate translation of all CAD/CAM data is critical to maintaining a digital thread in manufacturing. Verisurf is said to be the only measurement, reverse engineering and inspection software built on a full-featured 3D CAD/CAM platform with intelligent MBD. This is designed to ensure data integrity and enable users to perform metrology workflows in a seamless CAD environment while maintaining model-based digital continuity.

Verisurf software is compatible with all CAD file formats, and the Verisurf Device Interface (VDI) communicates with all 3D measurement devices for universal compatibility. Verisurf’s modular design enables users to quickly shift from reverse engineering to inspection to tool building, efficiently capturing and processing measurement data for all 3D metrology applications with repeatable process control across the manufacturing enterprise.

Related Content

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

-

Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

.jpg;maxWidth=300;quality=90)