Enhanced Utility Programs Streamline CAD Data Transfer

The 5.0 versions of Kubotek Kosmos’ interoperability products have been rebranded and enhanced with updated CAD file support and improved review/reporting capabilities.

Kubotek Kosmos (previously Kubotek3D) has release version 5.0 of its CAD/CAM software interoperability products: Validate, Revision, Convert and View. These CAD utility programs use proprietary Kubotek Kosmos modeling technology to support transfer of precise CAD data across the manufacturing supply chain. This release drops the K-Compare and K-Display brand names and provides updates to CAD file readers and user interface improvements. The new software is available for customers to download immediately.

To assure customers are prepared for any CAD files sent to them, reading of 3D CAD files across all 5.0 Kubotek Kosmos software programs has been updated to support new versions of nine CAD file formats:

- Autodesk Inventor 2023

- Dassault Systemes (DS) CATIA V5 R2023x

- DS V6/3DExperience R2023x

- DS SolidWorks 2023

- DS Spatial ACIS 2023

- PTC Creo 9.0

- Siemens Digital Industries Software (SDIS) NX 2206

- SDIS Solid Edge 2023

- SDIS Parasolid V35

The 5.0 update to these programs provides users the option to review additional metadata, such as text and values related to entities in the original CAD format. Kubotek KeyCreator support has also been updated to the 2023 CKD file format in 5.0 Validate and Revision products.

The Kubotek Kosmos Revision and Validate products, formerly branded as K-Compare, are said to enable absolute clarity in engineering changes and movement of 3D data with confidence. Both products are able to quickly read the structure of complex 3D CAD models from all major MCAD applications.

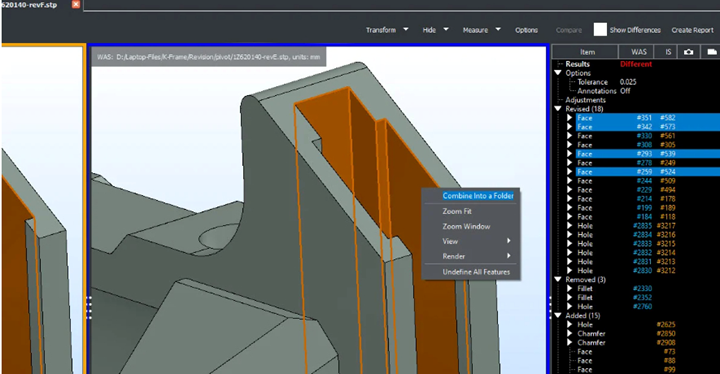

Revision report-building has been enhanced with a new annotation function to attach precise angle measurements to sets of points or linear edges on the 3D model. Custom organization of the differences the software finds between revisions of a CAD model has been improved: the user can now select sets of faces of a model in the graphics window to be combined into a single difference for the report.

The 5.0 release of Validate improves support for comparison of point cloud and triangular mesh derivative model data to the original CAD authority model. When the software detects differences, points are now named and listed in the user interface to aid in locating the problem area(s). The tamper-proof validation report has also been enhanced with a PASS or FAIL text note to support search and external automation.

Kubotek Kosmos View and Convert, formerly branded as K-Display, are easy-to-use, multi-platform applications which enable anyone to open and review nearly any MCAD file and re-publish models to standard formats. The 5.0 release expands the program’s capability to discover assembly structure from 3D models with a new function named BOM. The BOM function automatically creates a table listing/counting unique parts, based on assembly structure in the file or analysis of geometry. Balloon annotations are automatically created pointing to each part occurrence in the file.

The capability of the Convert product to write models to standard CAD formats has been expanded for 5.0 to support saving Parasolid X_T files (Premium level only). The Parasolid format is important, as the native B-Rep solid/surface format of popular products such as SolidWorks, NX, Solid Edge and Mastercam.

Related Content

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreVIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)