Automated Multi-Spindle Program Improves Long Part Machining Productivity

ESPRIT CAM’s offset-aware programming of spindle transfers and bar pulls, ESPRIT TNG CAM, helps manufacturers drive multi-channel CNC machinery accurately throughout complex operations.

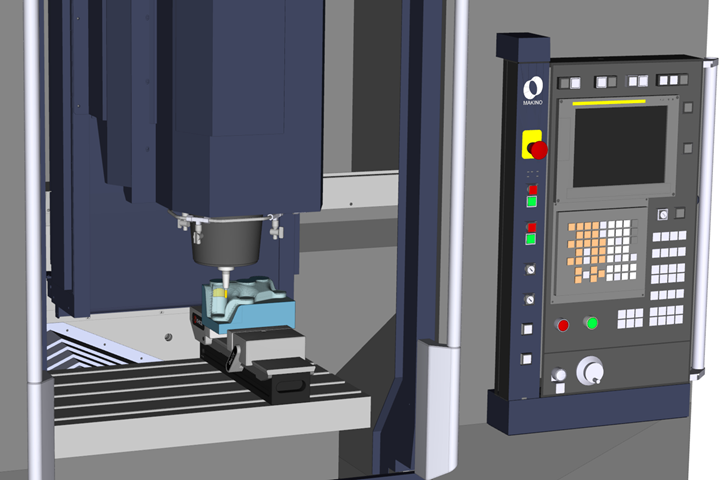

FreeForm three-axis cycle. Photo Credit: ESPRIT CAM

New CAM technology has been introduced by ESPRIT CAM, part of Hexagon’s Manufacturing Intelligence division that provides manufacturers with the control and flexibility needed to use multi-spindle and multi-channel CNC machinery for the machining of long parts. According to the company its new software, ESPRIT TNG CAM, offers more accurate simulation of spindle transfers and bar pulls, enabling manufacturers to exploit multi-tasking machinery with high productivity program creation of error-free toolpaths.

ESPRIT TNG now automatically tracks the location of work offsets regardless of part position by enabling programmers to define the offset and offset translations, or the points at which offset changes occur. In addition to enabling precise simulation, this is said to eliminate the need for custom settings or calculations to the machine post to ensure that parts are machined accurately and makes it possible to program a greater number of complex machining scenarios without error.

The new software also enables manufacturers to perform face-milling operations with a unique “roll-in” lead-in strategy recommended by Sandvik Coromant to improve surface quality, reduce cycle time and extend tool life. ESPRIT CAM says this lead-in technique positions the cutter for ideal thick-to-thin chip formation, which indicates that the insert engages the material deeply enough at entry to make a significant cut before exiting smoothly to reduce vibration and ensure consistent, high-quality surface finish. In addition to being less damaging to cutter inserts, this strategy eliminates the need to manually calculate face-milling stepovers during the programming process, which automatically ensures a consistent and even surface across the entire workpiece.

The new release also offers productivity benefits for three-axis operations. Toolpath creation is now reported to be 20 times faster, meaning that toolpath that once took 30 minutes to generate can now be calculated in about two minutes. Furthermore, a new three-axis toolpath can now be created in ESPRIT TNG from an existing operation without recalculating the entire toolpath. Areas in collision can be trimmed from toolpath generated for use with short cutting tools, or re-machining operations can be created with a long tool to cut only areas that cannot be reached with the shorter tool.

ESPRIT TNG 4.7 is now available from ESPRIT CAM.

Related Content

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.