High-Frequency Milling Suits Compact Gantry Milling Machine to Moldmaking Tasks

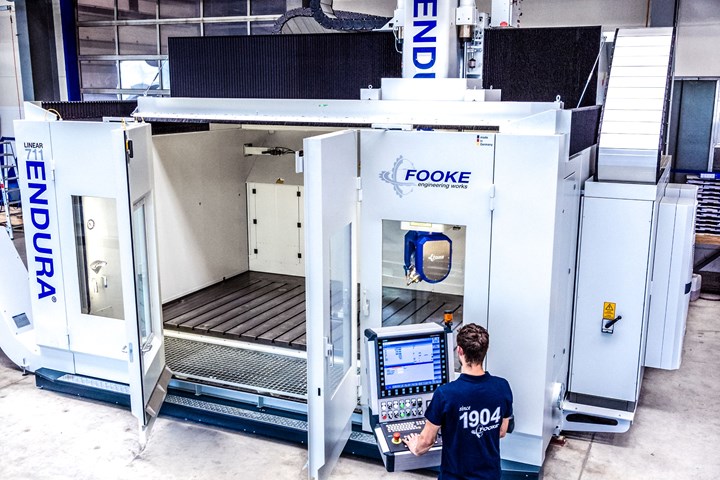

German-made Endura 700Linear series from Fooke is capable of various machining workpiece tasks, including composite, aluminum, cast iron and steel for mold and die-making.

The German-made Endura 700Linear series from Fooke, a specialist for large and very large gantry milling machines, has been sold and proven in numerous applications, the result of its power and reliability. Machines in this series have been continuously optimized since 2004, characterized by an optimal ratio of structural rigidity and motion control, combining for high productivity and improved machining quality. The series also meets customer expectations in terms of a large machining area, a small footprint and foundationless installation.

A large, compact Endura 700Linear portal milling machine features travels up to 5,500 × 3,500 × 1,500 mm (X, Y and Z). The modular layout enables an extension of X-axis travel to an XL version. Its intelligent design enables it to be installed on a solid industrial floor, Fooke says, and takes only a few days to be assembled and put in operation.

The series’ five-axis options are equipped with direct drives in all axes (linear and torque motors). Different milling heads with high-frequency milling spindles (HSK63A or HSK100A) can be selected. Thus, this series is available for various machining tasks; whether for machining CFRP/GFRP workpieces in the aircraft industry, modeling block material and aluminum in model and prototype construction or cast iron and steel in mold and die-making.

Consistent high precision due to the machine’s temperature stability, and thermal decoupling from short-term temperature fluctuations through Thermo Guard are additional features.

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.