A Showcase for the Latest Technology for Liquid Silicone Rubber (LSR) Molding

In conjunction with industry leading flashless mold manufacturing partner Roembke Mfg. & Design, Inc. (Ossian, IN), Shin-Etsu Silicones of America (SESA: A U.S. subsidiary of Shin-Etsu Chemical Co. Ltd., Japan), will be a co-sponsor of Roembke’s “Innovation Days” event at their facility on September 25th and 26th, 2012. The objective of the event, which coincides with Roembke’s 35th Anniversary, is to showcase the latest technology for Liquid Silicone Rubber (LSR) molding with a wide array of industry leading supply partners.

In conjunction with industry leading flashless mold manufacturing partner Roembke Mfg. & Design, Inc. (Ossian, IN), Shin-Etsu Silicones of America (SESA: A U.S. subsidiary of Shin-Etsu Chemical Co. Ltd., Japan), will be a co-sponsor of Roembke’s “Innovation Days” event at their facility on September 25th and 26th, 2012. The objective of the event, which coincides with Roembke’s 35th Anniversary, is to showcase the latest technology for Liquid Silicone Rubber (LSR) molding with a wide array of industry leading supply partners including:

Arburg (Newington, CT) / Design Facts, Inc. (Fort Wayne, IN) / Dow Corning Corporation (Midland, MI) Engel Machinery North America (York, PA) / Fluid Automation, Inc. (Wixom, MI) / GSDI (Barberton, OH) / Kistler Instrument Corp. (Novi, MI) / Kruse Analysis (Naples, FL) / Milacron LLC (Cincinnati, OH) Momentive Performance Materials, Inc. (Columbus, OH) / RJG, Inc. (Traverse City, MI) / Sodick, Inc. (Schaumburg, IL)

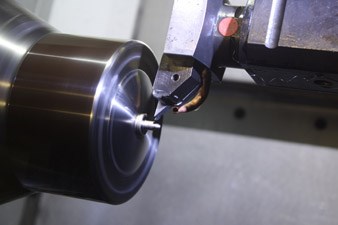

Notably, Shin-Etsu will be demonstrating their KEG-2000-50 LIMS (Liquid Injection Molding System) by molding a silicone duckbill valve using Roembke’s 2-cavity, valve-gated, cold-runner LSR mold. The KEG-2000-50 series is supplied in two components which are mixed in a 1:1 ratio to ensure easy and accurate blending with optimized physical and processing properties. Offering “Dynamic Viscosity,” KEG-2000 products exhibit higher viscosity under low shear stress (pumping and shut-off) and lower viscosity under high shear stress (injection). Customers benefit from faster mold filling and minimal flash.

Roembke’s flashless LSR tool is fully automatic−adapting the automation for the duckbill part to be de-molded automatically and allow the mold to run with direct injection with zero waste.

Additionally, a 3-axis robot from Milacron will remove the parts from the mold and internal mold pressure sensors from RJG will allow for complete control of the valve gates to balance the cold runner and monitor the internal cavity temperature and pressure. According to President Greg Roembke, “The whole cell works in synergy with Shin-Etsu’s KEG-2000-50 material which runs clean in the system and fully automatic within three shots!”

Shin-Etsu’s KEG-2000 LIMS products are engineered for outstanding performance in cold-runner systems with both open and closed-nozzle configurations and have consistent properties from batch to batch. They have high clarity and range in Shore A hardness from 10 - 80. Additionally, the products have been tested for compliance with FDA, USP Class VI, and ISO 10993 regulations.

Roembke’s 35 years in business has been primarily focused on flashless molds that produce high quality rubber products. For the past 10 years, additional focus has been placed on injection molds for HCR and LSR materials. In addition to Shin-Etsu’s KEG-2000 demonstration, other key partners participating on site during “Innovation Days” will include press and pump manufacturers, and material suppliers, as well as sources for automation equipment, in-mold sensors, and computer-aided mold flow simulation.

In addition to providing an excellent industry networking platform, attendees at the event will also be invited to a celebratory dinner on the evening of September 25th.

For more detailed information on Roembke Mfg.& Design’s “Innovation Days” event and to register. For more detailed information on the KEG-2000 series, visit the Shin-Etsu Silicones web site.

Related Content

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreMMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More