Regulations

Seeking Your Help! Moldmaking Customs and Practices Guide

The mold manufacturing industry is continually improving by joining forces on a variety of issues, challenges, technologies and trends. This time it’s updating the industry’s guidelines and practices to standardize and streamline the mold procurement process, and you can help.

Read MoreSafety, Finishing, Design, Virtual Learning: MMT's Top-Viewed Content

The MoldMaking Technology team has pulled together the content with the highest pageviews over the past 30 days. Check in to see what you missed or tackle some new topics!

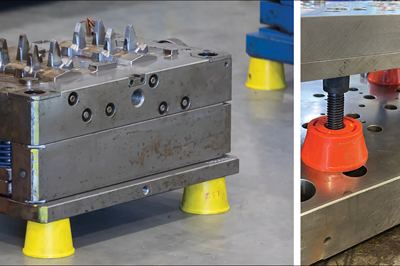

Read MoreMold and Plate Supports Enhance Shop Floor Safety

Progressive Components offers RhinoFeet and RhinoToes, support pads that eliminate trip hazards, elevate molds and hot runner systems and can be easily stored.

Read MoreMMT Chats: 5 in 5 with The Plastek Group (Tooling Divisions: Triangle Tool and Penn Erie)

MoldMaking Technology Editorial Director Christina Fuges has a quick 5-minute chat with Douglas Prischak, VP Global Tooling and Engineering for The Plastek Group in Erie, Pennsylvania, on five best practices for improving efficiencies. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchMold Cleaner Uses EPA-Exempt VOC Compounds

Slide Products’ X-EMPT mold cleaner guarantees air quality regulation compliance for plastic processors.

Read MoreThermal Protection Hose Enhance Occupational Safety

A braided textile glass fiber and a silicone foam coating meets injection mold temperature control requirements, improved mechanical properties and ease of use.

Read MoreFraud Risk Management Strategies for Mold Shops

Mold builders must understand fraud so they can reduce the risk and improve profitability and efficiency.

Read MoreLow-Leakage Temperature Control System Ensures Maximum Safety

The Hasco system showcases improved and robust quick-release couplings that guarantees safe and independent coupling with a maximum flow rate and a small, low-pressure drop.

Read MoreDo You Know the Hidden Costs of Poor Quality?

Mold builders must fully understand and account for the hidden costs of poor quality or risk losing customer trust, brand reputation and business value. Quality management is a business optimization tool to help address both the visible and invisible costs.

Read MoreEvaluating the Impact of Changes in Tax Rules and Accounting Methods

A look at regulations the Treasury Department released that are impacting mold builders.

Read More