Another Plant Tour at Amerimold!

Amerimold, SPE Mold Technologies Div and SPE Detroit Section Present Hi-Tech Mold Plant Tour.

Read MoreTechnology Power for Better Intelligence and Optimization at Autodesk Smart Manufacturing Celebration at Paragon D&E

Paragon D&E in Grand Rapids, Michigan, hosted Autodesk’s Smart Manufacturing Celebration last week to educate customers and fellow shops on how better intelligence for part and mold design can optimize overall manufacturing.

Read MoreThe Future Is Here, and It's Kicking Off at Amerimold

The future of making is here, bringing with it drastic changes in the way things are designed, manufactured and used. It’s disrupting every industry, including moldmaking, but with the right knowledge and tools, this disruption is your opportunity. Come to Amerimold to learn how.

Read MoreThis Just In ... Three Leadtime Leaders Form a Joint Venture

Mold Craft, Westminster Tool and Extreme Tool and Engineering formed a joint venture to maximize resources and offer the plastics industry a one-stop solution for engineering, moldmaking and production.

ListenTime to Share Your Top 10

MMT's annual "Top 10 Reasons to be a Moldmaker" contest reflects the community, camaraderie and sense of humor that has come to define the mold manufacturing industry. If your submission is selected, it will be printed on our annual t-shirt that is distributed at Amerimold from the MoldMaking Technology booth.

Read MoreAMBA Plant Tour Comes to Amerimold

MoldMaking Technology’s May issue has a story about Quest Industries and its unique approach to scheduling to accurately predict mold deliveries. But what makes this story extra special is that Quest has agreed to open its doors for an AMBA plant tour during Amerimold.

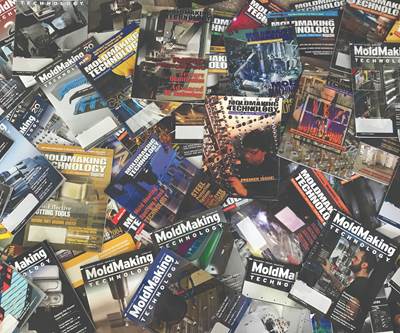

Read MoreMoldmakers Share Impact of MoldMaking Technology Magazine

Current and past editorial advisory board members and original supporting suppliers share what MoldMaking Technology has meant to their industry for the past two decades.

Read More3D Printing Workshop at NPE2018

New in 2018, the 3D Printing Workshop at NPE2018–The Plastics Show, is an immersive, half-day workshop focused on emerging technologies in 3D-printing and additive manufacturing impacting plastics and moldmaking.

Read MoreFAQs about Lasers and Moldmaking

After doing his own homework on laser engraving mold cavities, a reader reached out to MMT with specific questions about laser types, applications, wattage, work envelope size, cost and safety requirements. We then reached out to industry for some insight.

Read MoreMoldmaking's Relevance Withstands Time

If you asked me what the most important thing is that I’ve learned over the past 20 years it’s that moldmaking still matters. Despite technology and processes changing, moldmaking still matters.

Read MoreTop 10 Game-Changing Technologies

As part of our 20-year anniversary, readers share their top most impactful technologies since 1998.

Read MoreHow MoldMaking Technology Magazine Came to Be

Twenty years ago a moldmaker launched this magazine, legitimizing an industry and then passed it on to a passionate media company, which took it to the next level.

Listen