DNC Software for Moldmaking Shops

With the larger-sized programs moldmakers use, making sure programs are being run to their full potential should be a top priority, and DNC software can help.

Read MoreWorking Hands Radio

This tool and die guy, who has recorded more than 350 training videos, is now broadcasting on the radio with phone lines open. His first episode is on apprenticeships and mentoring.

Read MoreThrowback Thursday: Mold Maker and Mold Designer of the Year Award Winners

I am only throwing back to coverage of a few past winners to get you thinking about some potential nominees for this year’s SPE Mold Technologies Division Mold Maker and Mold Designer of the Year Award.

Read MoreDrop and Give Me 20!

Well,10 or even one of your top reasons for being a moldmaker today. Every year this industry shows off its wit and humor with our annual Top 10 Reasons to Be a Moldmaker T-shirts, so don’t let us down.

Read MoreFully-Coupled Analysis Brings Optimal Accuracy to Part and Mold Design

In the conventional analysis process, filling, cooling, packing and warp are separate solvers and will run analysis sequentially instead of simultaneously. Fully-coupled process simulation delivers simulation data in every time-step program, increasing analysis accuracy. Here is a look at the differences between conventional and fully-coupled process simulation for part and mold design.

Read MoreCollaborate to Educate on Plastics Technologies

Moldmakers, industry consultants and technology suppliers collaborate to educate on plastics technologies.

Read MoreGet Connected!

The annual AMBA Conference holds a special place in my heart. It has been a critical event for my career at MMT because of the relationships it has helped me build and the challenges and solutions it has revealed to me through its educational and networking opportunities. “Connect” with me at this year’s event next month.

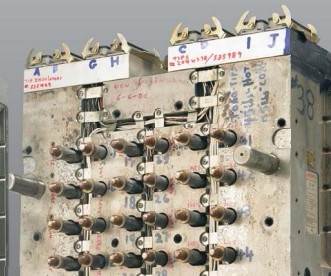

WatchThrowback Thursday: How to Prevent Hot Runner Leaks

One of the more common concerns still expressed by molders today about hot runner molds is the threat of a leak of molten plastic causing the manifold pocket to fill. Here is a throwback to an article on leak prevention focused on externally heated hot runner systems.

Read MoreAutomated Polishing: Commonly Asked Questions about Peening

Peening itself is not a new treatment, but that doesn’t mean it is fully understood. Peening is the process of working a metal's surface to improve its material properties, using mechanical means, such as hammering, blasting with shots (shot peening) or blasting of light beams (laser peening). Here are some commonly asked questions regarding the process.

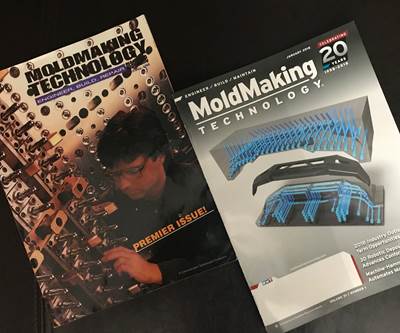

Read MoreMoldMaking Technology Celebrates 20-Year Anniversary

MoldMaking Technology (MMT) is celebrating its 20th anniversary in 2018. Founded in 1998, MMT remains committed to everything moldmaking, from design to first shot. This industry, which is utterly dependent on accurate, repeatable and efficient technologies throughout the design and build stages, was so worthy of a publication of its own. We are honored to celebrate this milestone with the industry and look forward to many more years to come.

Read MoreThrowback Thursday: Justifying Investment in Cleaning Innovations

For many shops, one of the most difficult aspects of implementing new mold cleaning technology is justifying the purchase, and this is still a challenge today. Here is a throwback article that covers the top six benefits of dry ice blasting for injection molds and the value of job tracking the overall impact of cleaning and maintenance.

Read MoreContinuing to Support Our Wounded Soldiers

The men and women of this moldmaking community never cease to amaze me with their care and generosity. Take for example, Tim and Kim Bartz launching iWarriors, which donates iPads to our wounded warriors. I encourage everyone to check out iWarriors and learn about what the program is up to today, and then consider giving what you can to those who give everything.

Read More