Growth of MMT Supporter and Leadtime Leader

It's always a good day when you hear of the success and growth of any reader of MoldMaking Technology magazine, but when it is a past Leadtime Leader Award winner and Editorial Advisory Board member, it is a little bit sweeter. Tech Molded Plastics, Inc.'s, a 2007 Leadtime Leader who has contributed much in the way of content to MoldMaking Technology magazine over the years, has expanded its facilities, which are now up and running. The company made major investments in facility up-grades, plasticizing technology, computerized monitoring of plastics processes, and advanced RJG training certification in plastics processing. Tech’s total footprint has almost doubled to over 92,000 sq ft.

Read MoreMichigan Manufacturing Boom

This year our annual amerimold event is taking place in a state experiencing a boom in manufacturing, and to some extent, reshoring is the reason. On that note, one of our keynote addresses during this event (June 13, 2012) will be on "How to Bring Manufacturing Back," hosted by Harry Moser, founder of the Reshoring Intiative.

Read MoreFuel Your Brain

FastTrack training program offers plastics professionals intensive training options.

Read MoreLeadtime Leader Takes on a Challenge

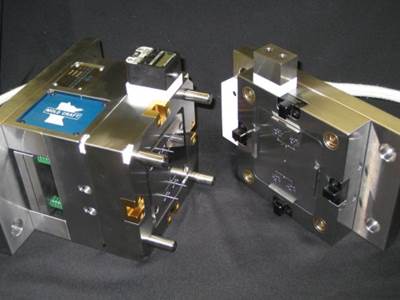

Can you really mold a pipette shaped part with a .015” wall x .370” long followed by a .008” wall x .080”? How about if the molding material is PEEK? How about 4 cavities? Can a Cpk of 1.33 be achieved on this wall section? These are the challenges and questions Mold Craft set out to prove the viability by partnering in flow simulation and press selection while Mold Craft designed and built a mold required for this difficult part.Although Mold Craft is typically known for their ability to design and build high cavitation production molds to produce parts that number in the hundreds of millions, Mold Craft has also received recognition for the ability to mold extremely tight tolerances on micro parts with intricate geometry that require high Cpk values. This challenge was just that, micro parts shaped like a funnel or pipette with extreme length to wall thickness ratio. To add to this complexity, the customer needed to use PEEK due to its high strength characteristics.Mold craft will be displaying their latest mold in the Sodick Plustech press at NPE in Orlando. Mold Craft (booth 1295) will have the attached photographed mold operating at Sodick Plustech booth 363.Read full story here.

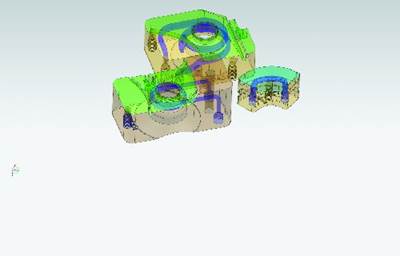

Read MoreConformal Cooling: Another Tool to Build a Better Mold

Moldmakers are just starting to scratch the surface of what can be done with conformal cooling, which involves an additive approach.

Read MoreAdditive Meets Subtractive

A supplement to MoldMaking Technology and Modern Machine Shop magazines.

Read More

.jpg;maxWidth=400;quality=70)