MMT Blog

Getting Ahead of the Curve

Standardization improves productivity and saves money for moldmakers.

Read MoreHow to Reduce Capital Equipment Expenses

Moldmakers can help molders reduce costs and maintain production with mold preservation - and maintain loyal customers in the process.

Read MoreThe New Future of Moldmaking

A new rapid prototyping technology can save moldmakers time and money.

Read MoreNick Hotujac: A Lifetime of Success

A moldmaker is duly rewarded for a lifetime of work and achievements.

Read MoreThe Ionic Fusion Process

Touted as an alternative to plating, ionization makes mold components harder, more lubricious and corrosion resistant.

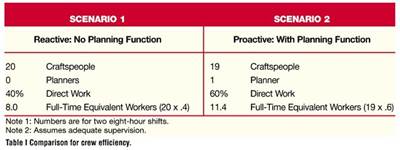

Read MoreManaging Maintenance Improvement Initiatives

The recent revision of ISO 9001 has again changed the standards landscape, placing the burden on manufacturers to define and measure their internal processes. Many are looking for a practical approach that gets the job done right the first time.

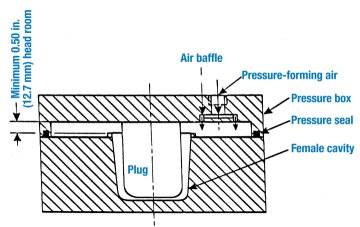

Read MoreThermoform Tooling for the Injection Moldmaker

By understanding thermoforming, injection moldmakers may be able to diversify their business by expanding into thermoform moldmaking.

Read MoreUnscrewing Components: One Good Turn Deserves Another

Choosing unscrewing components for your molds shortens leadtimes, reduces component costs and decreases cycle times.

Read MoreSample Time Acceleration Technology Explained

STAT is a whole system, not just a special tool.

Read MoreMicro-Matic Tool: Craftsmanship And Dedication Yield Repeat Business

Strong customer relationships coupled with innovative technologies guide moldmaker through tough times.

Read MoreSoftware Technology Trends Enhance Moldmaking Industry

In the recent NC Software Market Assessment Report, CIMdata revealed what technology trends moldmakers should be on the lookout for in the near future.

Read MoreMoldmaker Finds 10 Steps to Automation Process

An engineer-to-order ERP system may seem pricey at first, but the bottom-line results are the vital signs of every good moldmaker.

Read More