The New Future of Moldmaking

A new rapid prototyping technology can save moldmakers time and money.

As with many new technologies, the idea behind a new and innovative moldmaking technique came from the dream of an inventor - to create direct-to-metal molds quickly and cost effectively - addressing one of manufacturing's largest unmet needs. However, despite continuous attempts at creating a direct-to-metal solution, consistent success has been elusive. But a new, patented process has been developed called Ultrasonic Consolidation(tm) (UC) that may be the answer the manufacturing sector has been seeking.

How It Works

The UC process and its unique machine combine the features of machining and rapid tooling into a one-button system for aluminum tooling. UC works from CAD, applying sound-to-merge layers of metal and produce true metallurgical bonds - creating tooling with specific feature-to-feature accuracy within +/-.002" to .005", depending on geometry, over the machine work envelope of 24"x 36". The combination of additive and subtractive manufacturing processes allows features - which normally require EDM to produce - to be fabricated on a single machine, with a single program, in a single operation.

A special applications software system has been developed that runs on the user's PC. Machine codes are created from standard CAD, STL and IGES files, or processed NC machine data. The software is designed to simplify part viewing and generation, while ensuring high dimensional accuracy and surface finish quality.

The machine itself is a self-contained unit, about the size of a smaller NC milling machine, and is designed to fit into most any machine shop. The machine is driven by an industrial-quality control system. Features of the system include industrial PC, PC-based soft CNC with ISO-compliant G-code programming, modem remote diagnostic functionality and standard operator screens for easy viewing. Users also have been given the ability to stop or recover a build.

By using this material deposition method with aluminum tape, the need to create a plastic or wax pattern, make a mold, or cast and finish a part is eliminated. Consequently, UC is useful for producing aluminum tooling for plastic injection molding, blow molding, tire molds, molds for composite lay-up or any other aluminum tooling application.

Cutting Costs, Building Profits

Because of the "one-step" nature of this solution, users can reduce costs in the tooling phase of their product development cycle by up to a factor of four. For example, the manufacture of a 10" x 12" x 3" prototype injection molding tool can typically require multiple processes over a two- to four-week period and cost up to $20,000. This new machine and UC technology can build the same tool in four consecutive days at a cost of $5,000.

The unique UC process immediately gives users the ability to improve margins by producing and duplicating complete injection mold inserts quickly and accurately without design flaws or secondary processes. Once inserts are removed from the machine, the only additional step they require is polishing or texturing. This elimination of costly finishing processes enables low-volume manufacturing; achieves machine tool accuracy and surface finish in a single step; and enhances visualization and testing capabilities. Operation costs also are reduced when it comes to materials, training and maintenance. For instance, in certain situations, material costs for the aluminum (or other material) tapes are up to 70 percent less than other RP system materials. Since the specialized software simplifies programming and operation of the machine, mold shop owners are able to use less experienced moldmakers to produce low-cost tooling for their customers. Finally, the machine is designed to be customer-operated and maintained, so there is no need for investment in long-term maintenance contracts, although the company offers them to interested users.

Timesavings

Often, timesavings are more important to moldmakers than cutting costs. With the new UC technology, users can produce a make-like-production tool; mold a few parts in various materials, colors, etc.; and obtain test-worthy parts in about the time it takes to produce a model of a part using existing RP technology such as stereolithography. This allows users to validate design decisions earlier in the production process at a lower cost (time and money) than other methods.

In addition, the one-step system produces tooling that can fabricate not just a few dozen, but a few thousand parts. This capability allows use for bridge tooling to support a product launch while hard tooling is manufactured - shortening leadtimes and reducing risk of design flaws.

User Benefits

This aluminum tooling solution allows parts to be produced quickly and inexpensively enough to supply parts in the designer's exact material of choice for both consumer and functional testing. This enables the design and manufacturing functions to work closely, and makes it cost effective to create tooling very early in the production process. As a result, manufacturing processes can be validated during the design and test cycle and appropriate adjustments can be made.

Also, many existing rapid tooling processes are limited with respect to the size of the tools that can be produced. The large 24" x 36" work envelope of this machine allows molds from large to very small to be fabricated with a high degree of accuracy. An added benefit is that multiple small molds can be fabricated simultaneously.

Confidentiality is another area where UC benefits manufacturers. The protection of new product designs is an area of increasing concern as product choices proliferate and design consciousness expands. Rapid tooling processes that are suitable for internal use by design and development engineers enable companies to keep sensitive product data in-house during the prototyping cycle. This ability reduces the risk incurred by releasing any part of product development to outside toolmakers.

Related Content

Mold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

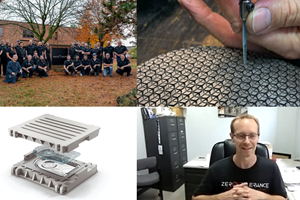

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreRead Next

Delving into Rapid Prototyping Technologies Attracts New Customers

Offering RP services and investing in technologies that help to constantly improve those services can help you reach potential new markets and allow your company to push the envelope of mold building technology.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)