Sample Time Acceleration Technology Explained

STAT is a whole system, not just a special tool.

Sample Time Acceleration Technology (STAT) is a hybrid of both traditional and composite tooling technologies. Through proprietary design, standardization, refined material usage and special digital technology, the disposable STAT system is so advanced that actual injection molded parts can be produced in a matter of days. This article discusses the steps to building a STAT tool. RP-processed parts are in almost every STAT tool and are supported by the formation of composites in round or oval sphere shapes - because a sphere is the strongest shape and yields better material usage.

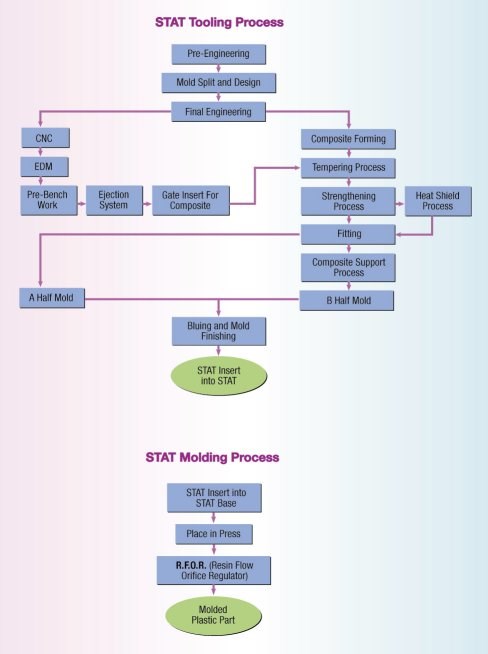

The tempering technology used in STAT tools (trademarked as RP tempering) is still evolving and will be used in other RT and RP applications in the future. This tempering process is performed in two steps: (1) the bottom layer of the tempering process for strengthening the composites; and, (2) the top layer of the tempering process for heat deflection.

The composites must be tempered so that they can withstand the heat and pressure of the injection mold press. Every STAT tool yields a part out of the actual resin of choice. A resin flow orifice regulator (R.F.O.R) has been developed specifically for the STAT tooling and molding process, which helps extend the life of the STAT tool - especially when the composites come into play.

Engineering considers the tempering process during mold split and design, during which the part file is manipulated to account for the thickness in the tempering process, and the different tolerances of the processes and resins used.

STAT uses lean manufacturing techniques, JIT ideologies and cell manufacturing. It's like an assembly line pushing aside traditional tool building methods as well as a mind-set that takes the average trade professional six months to adapt to the speed of the STAT tool assembly (see Flow Chart 1).

Extensive research with unconventional materials used in the STAT tool helps to decrease the need for expensive toolmaker's time, EDM time and CNC time. The STAT system only needs a team of 11 people to yield 30 to 35 STAT tools per month - ranging in size from very small fiber optic connector (1/4-inch square) to 19" x 21" parts.

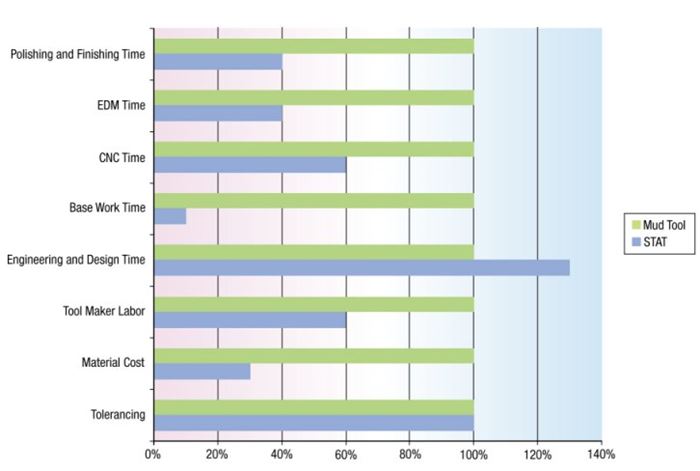

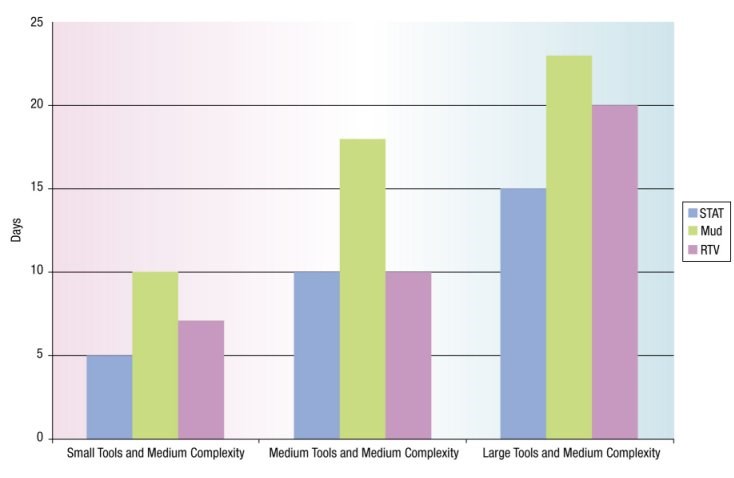

The STAT system uses a CAD file manipulation process to compensate for the poor tolerancing in the composites used, the material shrinks and the tempering layers. The end result is a tool that yields a part representative of a production-tooled part. Although STAT is not a class "A" production tool, it will produce a quality part 90 to 95 percent versus a production tool, but much faster (see Graph 1 and Graph 2).

The next generation of STAT technology is currently underway. Testing is being performed to see how much the tempering technology enhances SLA, SLS and RTV parts. The belief being that it will enhance the strength, durability and heat deflection of RP parts. Look for updates and applications stories as soon as the tool is proved out and the tests are completed.

Related Content

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

-

How Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.