MMT Blog

MMT Chats: Redefining Human Resources to Take on Recruitment, Retention and Mental Well Being

MoldMaking Technology Editorial Director Christina Fuges brings back EAB member and Human Asset Management Founder Marion Wells to talk workforce 2030, human resources and marketing. She strongly believes that mold builders must consider hiring human resources analysts to collect and analyze data to paint a picture of what's going on within their organization with regard to people, process and technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchTechnology and Sourcing Guide 2023: Inspection/Measurement

Inspection and measurement equipment includes all of the tools and devices used to verify that mold and part dimensions conform to the tolerances required by the part’s design

Read MoreMoldMaking Conference Session Spotlight: Software

Want to learn how to leverage CAD/CAM to streamline your moldmaking process or how to engineer cooling efficiency?

Read MoreHot Runner Tips, Apprenticeships & Waterline Maintenance, Oh My! MMT's June Top Hits

Take a look at MMT’s top hits from June based on Google Analytics.

Read MoreVIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

WatchMoldMaking Conference Session Spotlight: Data

Want to learn about digital workflows in mold design or ERP or global mold monitoring and asset management or the impact of tooling digitalization?

Read MoreTechnology and Sourcing Guide 2023: EDM

EDM refers to wire, sinker and small-hole electrical discharge machining. Components include drives, generators, programming, flushing, wires, electrodes, graphite, filters and fluids.

Read MoreTechnology and Sourcing Guide 2023: Machining

Machining shapes metal workpieces. Understanding both traditional and advanced machining techniques is critical to overcoming the various dimensional and finish challenges.

Read MoreMoldMaking Conference 2023: Education, Collaboration, Innovation, Discussion - Early Bird Discount Ends July 31st!

The moldmaking community will gather on August 29-30 in Minneapolis, Minnesota for a two-day technical program co-located with the Molding Conference. Here is a sneak peek at the sessions.

Read MoreTechnology and Sourcing Guide 2023: Mold Components

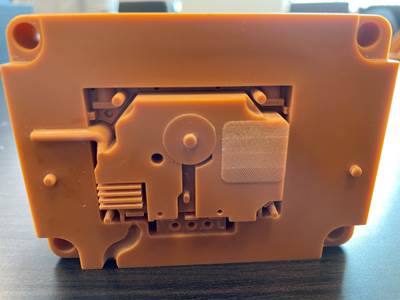

Mold components make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

Read More5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

As manufacturing advances with additive, the advance increasingly emphasizes these five themes.

Read MoreMoldMaking Conference Session Spotlight: Workforce Development & People Operating Systems

Want to learn what a people operating system is and what's really holding manufacturing back?

Read More

.jpg;maxWidth=300;quality=90)