User-Friendly Quality Standards

The 21st Century will come to be known as the century of quality. Join the movement or suffer, because the highest level of quality is not an option anymore, but a requirement to stay competitive in business.

Quality moves to the forefront in the plastics world. Do you recall when the word "quality" was likely to be part of a company slogan rather than a guarantee - a goal often sought but not achieved, a promise made easily and just as easily forgotten? Moldmakers and molding companies - small, medium and large - are not likely to get away with it anymore. If the 20th Century is remembered as the century of great production, the 21st will come to be known as the century of quality. Join the movement or suffer, because the highest level of quality is not an option anymore, but a requirement to stay competitive and stay in business.

Quality professionals' views, in short, are that quality improvements are the way to survival and profits. Quality means survival. It means more than just better products - it also means less waste, greater efficiency, better incomes, lower costs, more profits, lower prices and more satisfied customers. Moldmakers and processors today use standardized reports to disclose financial results.

The 21st Century companies will provide standardized quality achievement reports as well; i.e., ISO 9001 and QS-9000 (see Figure 1). Mathematical relationships will be established between quality performance and profits. Concurrent engineering and design-for-manufacture and assembly (DFMA) techniques will produce products and components quickly and cost-effectively. Your services need to include preliminary technical and financial analyses, concept and product development, complete simulation capabilities, modeling and prototyping, tooling design and construction.

The tooling and design engineering departments are the reasons why mold-making shops implement ISO 9001 in the first place. ISO documentation and procedures keep track of every revision level on every tool and help grant warranties, which guarantee every tool engineered and built for the life of the product. Using the data provided by the customer and in-house engineering, machining of components and cavity steel can begin almost immediately - sometimes before the design is completed.

CNC equipment, including mills and EDMs, are calibrated every six months. An ISO-based business plan followed to a "T" brings amazing results. Quality, customer service, advanced technology and knowing how to use it and - perhaps most important of all - employee empowerment: These are the key ideas in the moldmaker's business plan built into every square foot of the shop.

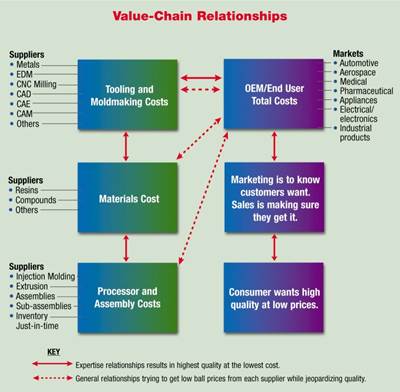

We are in an era of rising quality and falling costs. This is accomplished by pursuing quality goals deep into the process of obtaining raw materials, up through design and moldmaking to the production of parts.

The first step that moldmakers need to take is to learn how to use process mapping for greater productivity/customer focus. Learn process mapping from the leading experts in the field or outside consultants with tooling and processing knowledge. Master the techniques required for business process improvement - and get results quickly. Hands-on training courses have been developed for moldmakers' staff responsible for managing processes and improvement within their organization. This hands-on experience with limited class size can be conducted on-site upon request. Moldmakers will learn:

- How to identify key processes,

- How mapping leads to business process improvement,

- How to manage group dynamics,

- How to create maps with software,

- How to convert a paper system to an intranet solution, and

- How to upgrade to ISO 9001:2000.

Basically, a quality system is designed to reduce the causes of variables as much as possible in every area. And it is supported by documentation that demonstrates stability. The idea of reducing the causes of problems also drives customer service programs. A moldmaker is a full-service supplier, pro-viding design, engineering, tooling, prototyping and production services. In moldmaking everyone is responsible for maintenance. Toolmakers are trained to work clean rather than clean up work areas, thereby reducing yet another cause of problems.

A moldmaker's mission is to offer supply chain solutions as a single-source, strategic, world-class supplier. To do this, they must be flexible in adapting to customer needs. In effect, they need to be able to react immediately. World-class moldmaking is a process of continuous improvement in the entire operation, including quality, delivery, costs and lead times.

Moldmakers' greatest asset is their people, and fostering communication between them is the key to utilizing their talent internally. Likewise, communication with suppliers and customers keeps their operation in sync.

A well-defined "user-friendly quality standard" for moldmakers and molders will satisfy the minimal requirements of ISO 9001, QS-9000 and compliance with FDA GMPs.

These nine steps illustrate just how to implement such a user-friendly quality standard:

- Implement up-to-date training tools, including re-engineering, lean manufacturing and total quality management.

- Reality checks (performance monitoring and improvements).

- Process mapping for greater productivity.

- Workflow streamlining.

- Standardization.

- Supply chain management.

- Internal/external improvements.

- Standards and regulations requirements.

- Customer focus/customer satisfaction analysis.

Times have changed, and, more than ever, quality is essential to a moldmaker's health and survival. Quality should not be just a claim or a boast, but a scorecard to be used by customers, suppliers, investors and others.

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreMMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

Read MoreRead Next

Are You Ready for ISO Certification?

ISO certification just may give you the competitive edge that you need to survive in this economy.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More