Photo Credit: (top left) Xebec Deburring Technologies, (top right) Kruse Training, (bottom left) Cheto and (bottom right) HTS.

We’re heading into 2022 with a compiled list of the top products that you, our readers, have checked out the most this in 2021. This year has seen an abundance of new and optimized technologies, equipment and services covering the spectrum of categories MMT represents, further exemplified by the software, mold components, surface treatment, mold materials, machining and other product focuses below.

Note that, based on Google Analytics, these products with 2021 publish dates were pulled from between Jan. 1, 2021 and Nov. 2, 2021, and identified by their number of unique page views, which represents the number of times the specified page was viewed at least once.

Enjoy some of the favorites below, or see what you might have missed! Don't forget to look for some of these items in our December print issue or digital edition.

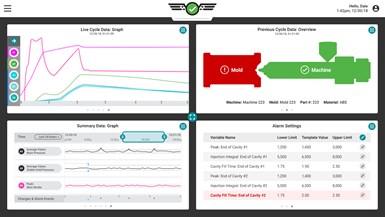

RJG’s CoPilot injection molding process control system is designed to be a user-friendly platform for producing high-quality parts. The CoPilot system enables users to observe what is happening to the part and identify when a process strays from the template, according to the company.

Photo Credit: Smith Enterprises

Smith Enterprises’ custom core pins expand DedTru systems grinding capacity with dimensional repeatability, accurate tolerances and concentricity within 0.001-0.0002. Ideal for medical and electronic applications, the core pins are suited for high-cavitation molds running 24/7. Consistent dimension control enables simple core pin replacement at required maintenance intervals.

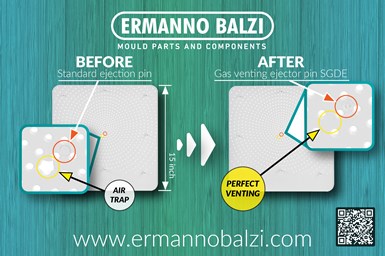

Photo Credit: Ermanno Balzi

To help resolve common effects that result from poor cavity venting, Ermanno Balzi showcases its Internal Dynamic Valves SGD and ejectors SGDE, which, due to a larger venting surface and punctual positioning of the valve, are said to overcome most performance limitations common to standard venting options. In addition to achieving better quality parts and reducing scrap during production, the company says its dynamic valves also enable reduction of injection pressure and injection time.

Photo Credit: Progressive Components

Progressive Components introduces the C-Series UniLifter mold undercut release system, which is able to compensate for misaligned mold ejector plates.

The new C-Gib features a cylindrical surface that the C-Coupling travels along when ejecting a molded undercut. Said to be able to self-adjust in both the X- and Y-axis, smooth travel along the black-nitrided surfaces reportedly prevent stress and wear between core blades and mold inserts.

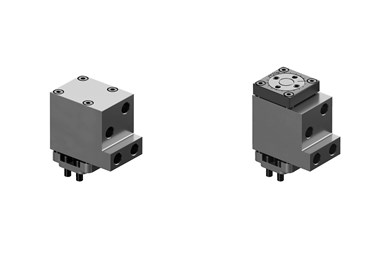

Photo Credit: Superior Die Set

Superior Die Set’s Threadformer unscrewing devices are designed to provide a simple solution for complex unscrewing molds, alleviating the difficult task of unscrewing molds without compromising the part. According to the company, a compact, yet highly powerful hydraulic motor rotates the core holder in and out of the mold.

Photo Credit: Xebec Deburring Technologies

Xebec Deburring Technologies’ ceramic fiber brushes are ideal for deburring, cutter mark removal and polishing of molds following the milling process. They can be used like a cutting tool in a CNC or robotic machine for fast, automated deburring. In a recent test performed on a NAK Steel Mold part, Xebec found that an automated finishing solution with Xebec Brush was 57 times faster than manual methods performed by skilled workers.

PFA Inc. offers a quick mold change (QMS) system ideal for non-magnetic mold clamping with consistent force and mechanical clamping advantages.

The PFA Hydra-Jaws QMC system replaces common mechanical clamp systems and bolt-through fastening methods with its flexible hydraulic mechanical clamping system for use with a variety of mold base dimensions and base materials.

Photo Credit: Ellwood Specialty Steel Inc.

Ellwood Specialty Steel Co., a steel supplier with divisions serving the U.S., Mexico and Canada, introduces its superior P20-modified grade of mold steel to the mold-building industry. Improved lens/texture quality (LTQ) alloy offers highly consistent surface finishing properties.

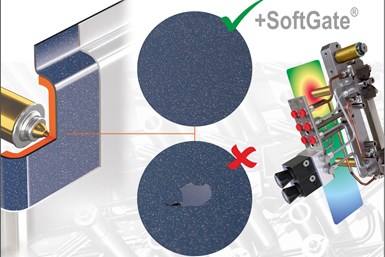

Photo Credit: INCOE Corp.

Several years ago, INCOE recognized the challenge of direct valve gating a part while overmolding film or fabric in mold decorating. For example, the “blast” of the plastic in the gate area can often damage the film or wrinkle the fabric. Using control technology, the company’s SoftGate Velocity VG pin enables these applications to be direct gated. This allows for the “gentle” flow of plastic into the cavity, eliminating blemishes that can occur with uncontrolled flow.

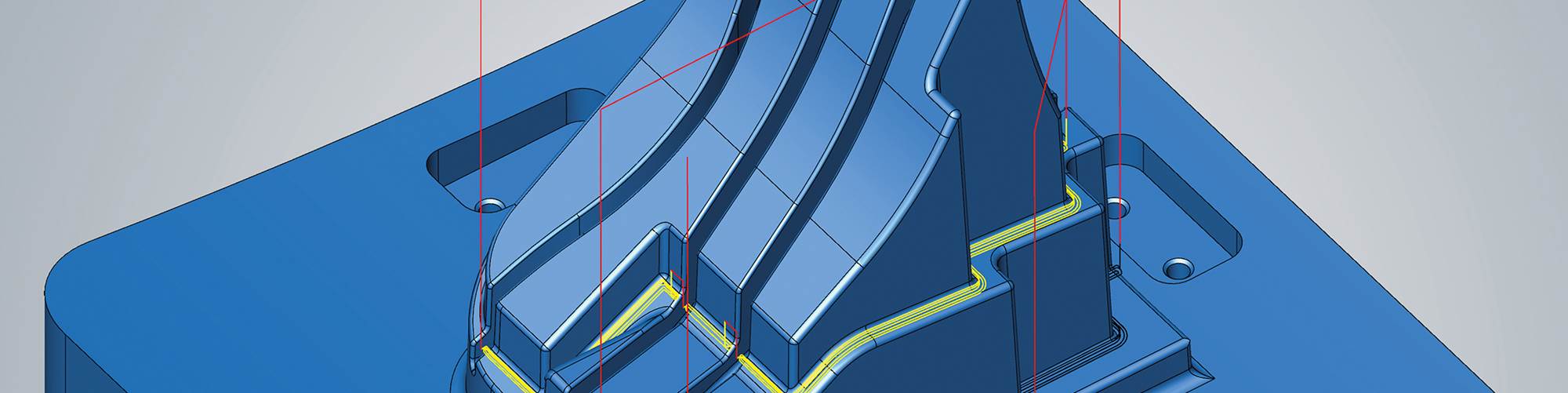

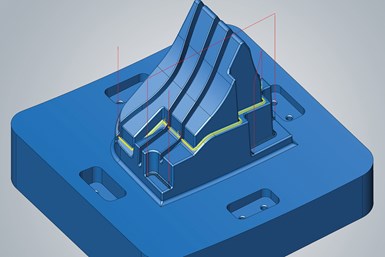

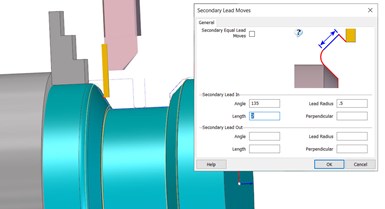

Photo Credit: OPEN Mind Technologies

OPEN MIND Technologies USA Inc. developer of global CAD/CAM software solutions, has released its latest hyperMILL 2021.1 CAD/CAM software suite which offers users new and enhanced features for efficient 3D, five-axis and mill/turn machining. Key innovations for more productive tool and moldmaking include a new “Interactive Edit Toolpath” capability which enables toolpath editing after initial toolpath generation.

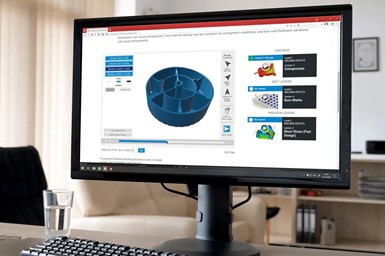

Photo Credit: Kruse Training

The “Circle of Knowledge” offered by Kruse Training is a holistic method that teaches the cause-and-effect behavior in injection molding, helping engineers become all-around molding experts. Kruse Training is an online program that provides an overview of how injection molding professionals, from entry-level to experienced engineers, can benefit from this comprehensive approach.

HTS iTherm, which can be integrated through any toolshop, with various options for manufacture, offers conformal cooling for injection molds, improving the ability to cool challenging inserts and cores, and often reducing cycle time or improving part quality. Material options include H13, 420SS and other standard tool steels.

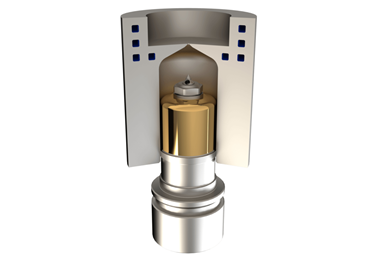

Photo Credit: Oerlikon HRSflow

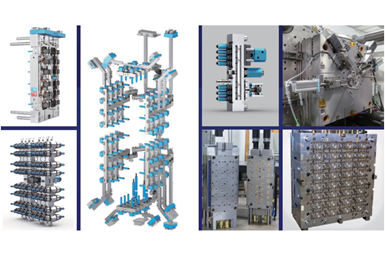

The S Series Cylinder by HRSflow for hot runner systems is a compact solution that enables reduced pitch and is suitable for technical materials.

With its compact shape, lowering plate thickness is now possible. A reduced width further enables a minimum nozzle pitch of 37 mm (1.46"). HRSflow offers two layout versions: The basic version offers a cutout height of 65 mm (2.56"), and the adjustable version, with a needle position that can be adjusted ± 1 mm, offers a cutout height of 73 mm (2.87").

The Almo company manufactures and supplies edge gate cutting pins used to separate the runner and gate on the edge of the plastic molding during mold opening. Almo has recently introduced a range of square cutting pins, which can be modified to the plastic moldings’ edge profile.

Photo Credit: Alliance Specialties and Laser Sales

Alliance Specialties and Laser Sales released the Alliance ID-1 Fiber Laser Welding System five years ago to change the way mold welding was being done. The goal, based on industry feedback, was to create a fiber laser system with a smaller footprint and a lower price point. This system meets both of those needs.

The ID-1 Fixed Workstation is a 300- or 450-watt fiber laser welding system on a budget, engineered for companies needing to repair inserts, components and smaller tooling.

Now offered in a Ø24-mm diameter, the CUMSA Sprue Adjuster (SA) family has been made available in 4 sizes. As with its smaller SA types, CUMSA says these sprue adjusters are offered in two versions—SA240022 and SA240822—which are suitable for molded parts which require larger runner gates, and are compatible with larger nozzle diameters up to 22 mm.

ANCA Inc. introduces AIMS (ANCA Integrated Manufacturing System), a system that connects sequential processes in tool manufacturing to facilitate streamlined tool production. Linking separate processes and factory IT systems to each other, AIMS simultaneously provides versatile, modular options for common manufacturing challenges to optimize cutting tool production.

The multitask gundrilling machine from Cheto is said to be a type of deep-hole drilling machine that maximizes the performance of the drilling tool. Thus, says Cheto, it is possible for the machine to drill holes at great depths and with extreme precision in any type of materials. Cheto’s machines are all in one: They are applicable for drilling (deep-hole and conventional), milling, tapping and boring.

Photo Credit: Westfall Technik

Westfall Technik has developed proprietary hot runner technology to produce parts ranging from 0.001 g to 400 lb. The easy-to-maintain hot runners are designed for longevity and reliability.

Westfall will also promote its advanced high-precision (± 0.001”) micro molding and high-precision, high-cavitation tooling solutions with integrated hot runners.

New and enhanced functionality in the latest release of EDGECAM CAD/CAM software from Hexagon Production Software boosts customer productivity with lower computer-processing time and faster toolpaths.

A number of these productivity boosts have been achieved by reducing calculation time with EDGECAM 2021’s enhanced parallel-processing capability. Two of the most popular machining cycles, Roughing and Profiling, are said to benefit from improvements to the software’s multi-threading technology algorithms.