This month’s Technology Showcase provides a comprehensive list of the supplier services and products that are highlighted in the upcoming MoldMaking Technology 2021 Technology Review and Sourcing Guide, an annual guide designed to give you easy access to valuable purchasing information.

All products/services are divided by category; there are 11 categories in all, including:

- Mold builders

- Software

- Additive manufacturing

- Hot runners

- Mold components

- Machining

- EDM

- Cutting tools

- Mold materials

- Mold maintenance, repair and surface treatment.

Each supplier is tagged for optimized access to their website, or additional information. Click on any product post title to be guided to the full article.

Check to see what you’ve missed (and what’s upcoming) below!

Mold Builders

Action Mold & Machining is a veteran-owned plastic injection mold manufacturer and repair facility in Grand Rapids, Michigan. Quick-turn repairs for manufactures has made the company the “emergency room for production tools.” As well as performing engineering changes, preventive maintenance and repairs Action Mold & Machining also builds new tooling. The shop is open around the clock for emergency needs five days a week, with Saturday and Sunday available as needed.

Westminster Tool Inc. specializes in complex, Class 101 injection molds with particularly challenging manufacturing dimensions and tolerances. In addition to serving the packaging and defense industries, Westminster Tool reports that it excels in the medical device industry, placing a high emphasis on strict dimensional requirements with long-term, repeatable results for medical device manufacturing.

Established in 1986, Canada-based Enterprise Mold Ltd. has spent its years diversifying its mold offerings for the mold manufacturing industry, from standard automotive and handicapped wheelchair scooter molds, to toys, sporting goods, agriculture and dunnage molds (large and small), as well as offering custom machining services.

Established in 1981, New York-based Accede Mold & Tool Co. Inc. is a highly-experienced, knowledgeable and competent full-service Class 101 mold builder and turnkey systems integrator that serves the global injection molding community.

With second-generation ownership and a third-generation workforce, Accede specializes in high-cavitation, stack and two-shot molds including rotary, in-mold-rotary, lift-and-rotate and cube-platforms for the medical, consumer packaging, industrial, defense and automotive industries.

According to MMT 2019 Leadtime Leader Award winner X-Cell Tool & Mold, with an increase of higher cavitation tools comes longer machine runtimes. In order to reduce uptime, as well as get steel to the heat treater faster, the company says it continues to invest and grow its technologies. This includes the addition of a new automated soft milling cell to generate increased throughput, as well as an automated five-axis PX30i machining cell from Yasda.

Cavalier Tool & Manufacturing is a global mold manufacturer established in 1975 with 220 employees throughout Canada, Latin America, India and the U.S., designing and building mid- to large-size molds. This mold builder’s Windsor, Ontario 66,000-square-foot facility houses technology that builds about 200 molds per year for 250- to 4,000-ton presses. Cavalier builds injection, structural foam, gas assist, multi-shot, thermoset, prototype or compression molds for the automotive, commercial, recreational, medical, heavy truck and agricultural industries.

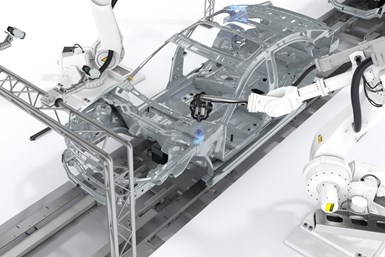

Industrial Molds, a division of Pyramid Molding Group, manufactures simple to complex molds for industries including medical, automotive, commercial appliance and consumer products. The company specializes in designing, engineering and special machining to create quality, precision tooling. Further, Industrial Mold’s automated, 24/7 unattended machining enables its team to work better and faster, while optimizing costs to its customers.

Since 1964, Michiana Global Mold (MGM) says it has been a world-class designer and builder of plastic and rubber injection molds for the automotive, medical, industrial and consumer products markets. The company specializes in Class A finish, highly complex and multi-material parts. Its cross-functional design and engineering team works in collaboration with all journeyman moldmaker craftsmanship to build single to high-cavitation molds for tight-tolerance parts including hot/cold runner, collapsible core, insert, overmold, shuttle, stack, unscrewing, two-shot and rotational.

Software

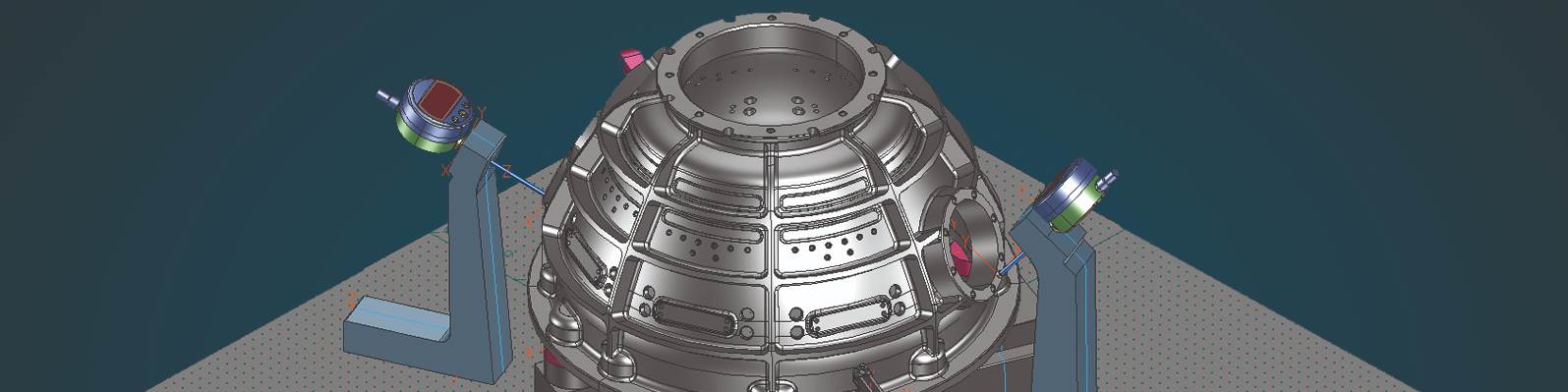

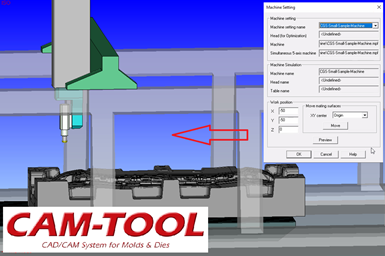

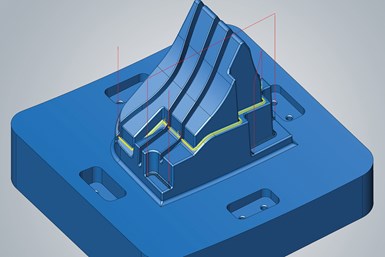

CAM-Tool by CGS North America, is a high-end CAD/CAM system that provides mold and die manufactures a wide range of modeling capabilities not found in “high-end” programming systems. For example, CGS North America notes that once a user’s data has been prepared, the calculation of the NC toolpath is completed by simply defining one’s machining strategy and cutting tools. CAM-Tool is said to do the rest, making sure the tool only goes where necessary to remove material using its optimization capabilities. CAM-Tool creates toolpath based on surfaces, and not a mesh, improving finish quality.

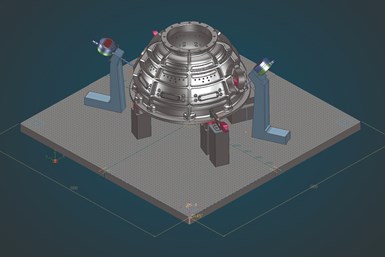

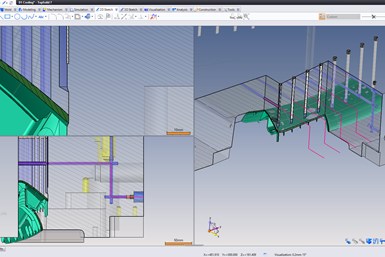

Tebis America Inc. has launched Tebis 4.1, a complete parametric- associative CAD/CAM system, which is said to provide seamless, highly automated mold, die and model design, development, programming and manufacturing in a single system.

The software platform is built on input from infield designers, for an intuitive and user-friendly structure. Additionally, Tebis 4.1 integrates measuring and production, resulting in shorter setup and machining time, higher component quality and fewer correction iterations. Finally, safety is improved by providing more flexibility to non-verified virtual machines to prevent potential collisions.

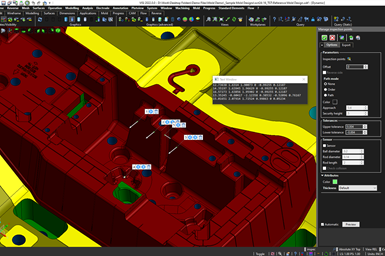

Hexagon Manufacturing Intelligence announces significant developments in CAD/CAM functionality of its latest VISI 2022.0 software release. Distributed and supported in North America by TST Tooling Software Technology, the software is said to give users additional speed and quality throughout their design and machining process.

CAD updates in VISI 2022.0 focus on the user experience and add enhancements to enable customers to speed up their design process.

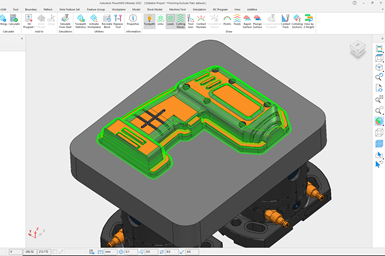

PowerMill software from Autodesk is a 3D CAM solution that offers three- and five-axis programming tools for complex part production. Continuing the theme of previous releases, Autodesk says the new PowerMill 2022 release includes a range of improvements and new capabilities aiming for optimized performance and user simplification. New highlights include improvements made to some of the software’s most commonly used finishing toolpaths.

New to the mold-related TopSolid 2021 CAD/CAM parametric software range (TopSolid Mold, TopSolid Progress, TopSolid Electrode and TopSolid CAM) within the TopSolid software family, is the ability to create waterlines based on pre-existing 3D sketches.

According to the company, the sketches can be made manually or via a pattern of sketches. From there, the waterline automatically adapts each circuit to each sketch based on user-definable rules. In turn, these rules enable control over the drilling and the components that are associated to each drilling. A baffle line for example, will automatically adjust the depth based on a user-defined offset point from the nearest detected collision. From there it will automatically put the trimmed baffle into the line.

OPEN MIND Technologies USA Inc. developer of global CAD/CAM software solutions, has released its latest hyperMILL 2021.1 CAD/CAM software suite which offers users new and enhanced features for efficient 3D, 5-axis and mill/turn machining. Key innovations for more productive tool and moldmaking include a new “Interactive Edit Toolpath” capability which enables toolpath editing after initial toolpath generation. The feature is reportedly easy-to-use, and offers programmers the flexibility to adapt toolpaths by trimming and removing sequences accordingly for component conditions.

Additive Manufacturing

Fortify has extended its Flux Series line for filled and fiber-reinforced photopolymers 3D printing to include two new printers and software to enable customers and partners access to develop new advanced materials. Funds from the company’s recent equity round will be used to scale up manufacturing of these printers for end-use part applications.

Next Chapter Manufacturing presents its NXC vented ejector pins which target the persistent problem of gas traps in molds. Unlike traditional venting methods, which lead to high scrap levels, cracking and weak parts that may result in rejections and lost profits, the company says its ejector pins, 10-15 times the venting volume over traditional venting, enable gas to exhaust out of the mold efficiently.

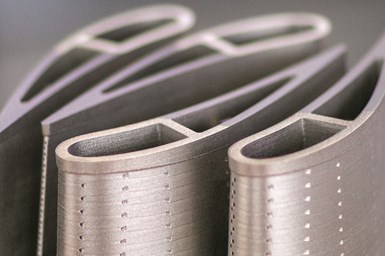

Matsuura’s metal 3D printing via its Lumex series enable the production of high-volume mold components with conformal cooling and integrated porous venting, minimizing the need for traditional EDM processes and reportedly providing significant savings for the production of molded plastic components.

The implementation of the Lumex machine emphasizes its success. Matsuura notes a metal injection molding customer added the Lumex Avance-25, a metal laser sintering hybrid milling machine to its new product development group, and reportedly reduced its market-entry tooling lead time from four weeks to four days.

EOS North America, an industrial 3D printing technologies supplier for metals and polymers, has added a new nickel alloy material to its growing list of metal powders available for use in powder bed additive manufacturing (AM).

The new material, EOS NickelAlloy IN939, is a nickel-chromium alloy that is said to offer a balance between strength in high-temperature settings, resistance to corrosion and oxidation, fatigue performance and creep strength at temperatures up to 850ºC (1,560ºF). EOS says its NickelAlloy IN939 provides users with improved tensile properties, validation, reliability and crack resistance compared to similar materials currently on the market.

Showcased during the Formnext Connection 2020 international exhibition and conference, Arburg’s Freeformer, an open system for the additive manufacturing of functional parts, combined with the company’s patented Arburg Plastic Freeforming (APF) process, is said to redefine plastics processing and meet demanding parts. Potential applications include medical technology, the processing of soft materials and polypropylene (PP) and additive manufacturing of multi-component parts.

EDM

The FANUC wire EDM machine, the RoboCut α-CiC series, from Methods Machine Tools Inc. has been redesigned from the bed to the control to give users ultimate ease of use and world-class performance, for elevated EDM capacity and increased throughput.

Design changes include a new table construction for better accuracy, a more straightforward auto-wire feeding panel and a new upper guide for easier maintenance and improved reliability.

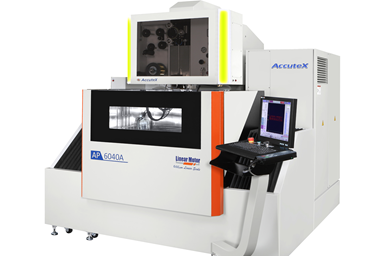

Absolute Machine Tools offers the AP Series wire-cut EDM machines, including the Accutex AP-6040A, for large mold component machining. These systems reportedly offer a highly rigid structure, Windows CE controller, new generation shaft-type linear motor, an ultra-resolution signal processor, cutting efficiency comparison, a corner control function, high cutting accuracy and new lead-in/lead-out control. Optional features include a CIMFORCE Industry 4.0-intelligent integration system, auto-wire threading and 0.05-0.1-mm fine wire application.

Sodick Inc. introduces the Sodick AL G Series Rigid linear motor-driven die-sinker EDM featuring its new High Performance SP Controller.

Fast and accurate for precision parts and molds, the next-generation precision die-sinker EDM incorporates a combination of the Rigid linear motor control technology—said to be the latest discharge control technology—and artificial intelligence. Among its enhanced features are Sodick’s “SP Power Supply,” “Arc-less 4 Circuit” and “LN Professional AI software.”

HCL Technologies (HCL) announces a new wire EDM module for the CAMWorks suite of CAD/CAM software. The wire EDM module includes new functionalities that takes the design model to G-code in one click. Once the user clicks the “Solid to G-code” button, the system automatically searches the part for machine-able features, identifies them, generates all the operations with the users’ preferences and settings (including tool offsets, cutting conditions and start holes), creates the toolpaths and posts the G-code. Complex two-axis parts, two-axis parts with tapers and full four-axis wire EDM parts are programmable under this module.

The ANCA EDG (Electro Discharge Grinding) is a high-performance rotary EDM machine platform has been refined to maintain the optimum spark erosion gap for both simple 2D- and complex 3D-path interpolations via Intelligent Adaptative Control (IAC).

IAC is an in-time, servo-controlled feature that automatically monitors and controls the erosion gap distance, in-process. Alternately, the Adaptive Spark Control (ASC) feature avoids over-eroding materials.

Mold Materials

Steel supplier Ellwood Specialty Steel Co. introduces its superior P20-modified grade of mold steel to the mold-building industry. Improved lens/texture quality (LTQ) alloy offers highly consistent surface finishing properties. Recognizing the increased demands for flawless diamond polish finishes on lens molds and complex geometric and delicate texture patterns, Ellwood says its metallurgists have engineered a steel that will perform to a user’s most stringent requirements. According to Ellwood, the P20 LTQ material is said to be the first steel to be fully qualified to General Motors’ GMQ 18157 mold steel specification.

Steel service supplier

International Mold Steel has recently grown its service capabilities to include offering laser engraving services in-house to its customers.

With the addition of a customized ID1-NGRV machine from Alliance Laser Sales, IMS says it can quickly and safely engrave steel with any information that will enable customers to better identify, track or brand their product.

Molder’s World Inc. announces the development and availability of its next-generation Vortex, a self-venting mold steel specifically designed for injection molding applications. This was specifically in response to the discontinuation of Porcerax II, and the company’s realization that they were not only able to replace it, but to improve on the qualities the industry had come to rely on.

Uddeholm USA features its next-generation Tyrax ESR stainless steel mold designed for a pressure ESR (P-ESR) manufacturing process that enables longer tool life, and faster polishing for reliable production of high-performance plastic parts. With a hardness capability of 58 HRC, the company says its product is the best in its class for toughness, corrosion and wear resistance.

Global supplier of high-quality mold materials Finkl Steel highlights the patented pre-hardened mold steel grade MD Xtra. The through-hardened material is said to achieve high impact strength, enhanced thermal conductivity and is an exceptional solution for deep cavity applications.

According to Finkl Steel, MD Xtra has proven through-hardenability on molds up to 45 inches in thickness, with hardness loss from surface to the core of roughly 3 HRC points. The material has been specifically engineered to support laser hardening, chrome plating, nitriding, texturing and has excellent weldability.

Hasco recently improved its P1 plates, which are machined on all sides and are said to fulfill all the requirements of modern moldmaking. Hasco offers at least 2,000 additional variants of this plate in dimensions, thicknesses and materials for high flexibility.

Materion’s MoldMAX alloys are said to meet the high-performance demands of the plastics processing industry, combining strength and thermal conductivity, as well as being polishable. Materion says these features enable a shorter cycle time and improved plastic molding part quality. MoldMAX alloys are said to be tailored for all types of plastic injection and blow molding applications

Hot Runners

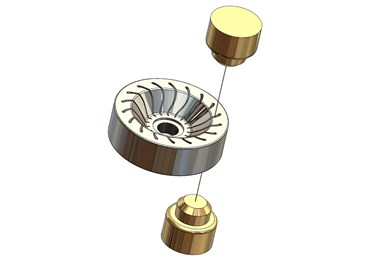

Mold-Masters’ new, second-generation SeVG+ (Servo Electric Valve Gate) motor is a compact, direct drive design that has reduced stack height by 48% (at an installed height of 114 mm), simplifies mold design and offers superior process control for demanding applications.

With a footprint of 108 x 108 mm, the servo motor is interchangeable with Mold-Masters’ hydraulic actuator for added flexibility. The design itself has been made compatible with the company’s full range of valve pin diameters (2.0-9.5 mm) and incorporates integrated water-cooling channels for high-temperature applications. It is also well suited with molds utilizing magnetic clamps.

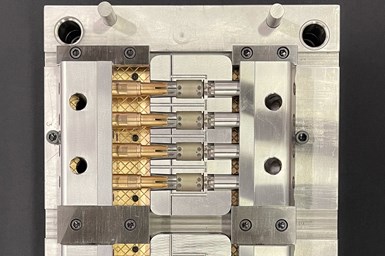

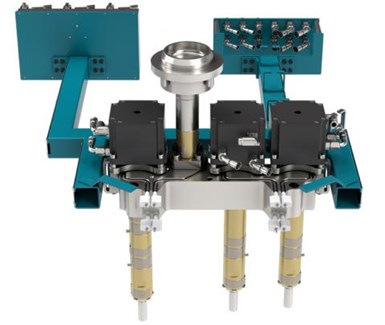

Husky Injection Molding Systems presents the UltraShot Injection System, a next-generation melt delivery and control system that is said to eliminate traditional injection molding process deficiencies and achieve risk-free scalability, improved capability and overall part design freedom.

UltraShot Injection System’s identical system behavior for each injection circuit provides process condition consistency with cavitation scaling. A predictable process from pilot to high cavitation—scalable to 128 cavities—enables producers to maximize cavitation without negative performance on balance or shot-to-shot variation.

Introduced in early 2020, Flexflow Evo is an advancement of Oerlikon HRSflow’s Flexflow technology for servo-driven valve gate systems used in injection molding. The electrical technology has specifically been designed to set and monitor the valve pin position during the injection process, resulting in an accurate, easy-to-operate solution. Actuators are directly fixed on the manifold, for a quick and safe ready-to-install system on the mold, and the updated software can be easily retrofitted to all existing control units. Further, the more responsive control unit, due to an optimization of the data transfer, enables flexible 360-degree flow control and monitoring for flow rate and pressure at each individual gate during the molding process.

Hasco’s hot runner control unit Primezone H1281 offers moldmakers a reliable system with high control accuracy, an intuitive interface and comprehensive diagnostic functions that guarantees stable processes and quality injection-molded parts.

Monitoring functions protect the controller, the hot runner system and the mold. Integrated mold diagnosis checks the wiring of hot runner components before start-up, and recognizes potential assembly errors, preventing mold damage and expensive repair costs.

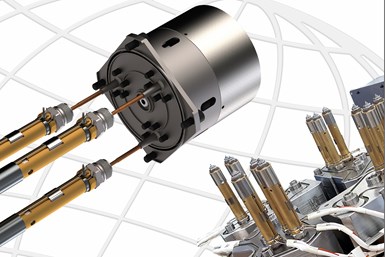

For valve gate applications in which multiple nozzles have to be positioned in the most confined space, and need to be opened and closed simultaneously, hot runner manufacturer INCOE has developed the pneumatic MultiPin valve gate actuator in two sizes and included them in its range of products.

Based on the proven PE pneumatic units and designed for the (Slim) DF 5 and (Slim) DF 8 nozzle series, the MultiPin actuators are said to support the interconnection of up to four valve gate nozzles with cylindrical valve pin tip (ZTT).

Global hot runner company Mastip recently launches the latest development in its Guided Valve Gate Tip range (GVG5) with a focus on durability, efficiency and long-term value. Delivering precise valve pin alignment for cylindrical gates, the GVG5 tip aligns the valve pin before shutting off in the gate to improve gate life.

Available in both thermal and valve gate options, the GVG5 tip range is engineered specifically to process highly filled engineering polymers with fillers like glass or carbon fiber, and talc.

Mold Components

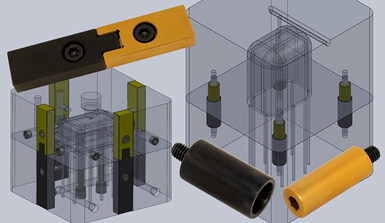

Progressive Components continues to introduce new mold component styles and sizes in order to meet every application need. This includes the expansion of its alignment lock product line with the Cavity, Flat Cavity and Round Cavity Interlocks for precise alignment.

Eliminating installation of mold base locks, the Cavity Interlocks mount directly into the mold's inserts. Sized for nominal plate and insert thicknesses, the highest amount of locking surface is provided for the minimum amount of space to be machined.

Flat Cavity Interlocks sizing begin at widths of 0.625 in., and lengths can be modified to suit the heights of the cavity and core inserts.

Extension of i-mold’s tunnel gate insert TG Series range with curved feed channels further supports compact injection mold designs for diverse application tasks.

Customers can choose between three sizes for shot weights up to 35 g (type I), 120 g (type 2) and 1000 g (type 3), as well as between three (low, medium, high) feed channel outlet levels. With these nine different configurations it is possible to optimize the sprue-to-molding volume ratio in applications involving large contour steps, moldings with a peripheral rim, or interior contours located above the mold parting line.

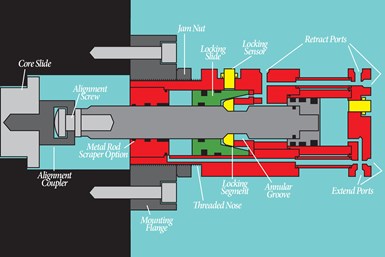

PFA Inc. provides a complete cylinder preloading and locking system for movable cores and core pulls on injection molds to help molders improve mold performance with off-the-shelf solutions, assisting in high-quality part production in a smaller mold footprint.

The PFA Kor-Lok side action system is said to have performance enhancements beyond standard hydraulic and locking cylinder systems with its ability to preload slides to high forces and maintain the force at zero psi, a feature different from many traditional spring-locking, hydraulic-activated solutions which often do not lock, preload, or maintain force without hydraulics.

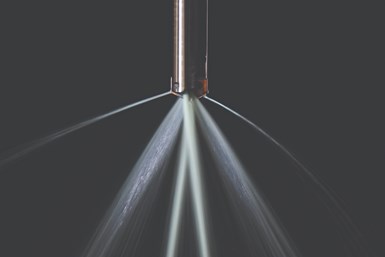

DMS’ dynamic SGD mold venting valve is an innovative solution that is said to resolve the most common effects of poor cavity venting when producing parts. According to the company, standard venting systems offer a venting capacity and performance that most of time is not sufficient to achieve reasonable part quality. However, “dynamic” venting valves — like its offered SGD mold venting valve product — act as alternative solutions which can be either external or internal to the cavity, and are designed to allow the air and resin gases to rapidly leave the cavity via a venting channel.

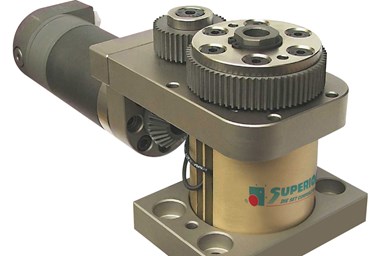

Superior Die Set’s Threadformer unscrewing devices alleviates the difficult task of unscrewing molds without compromising the part by rotating the core holder in and out of the mold via a compact, and powerful hydraulic motor. To guarantee a precise thread start position, the core holder runs against a fixed stop, which is typically the mold base.

DME’s proprietary Accualign Lifter possesses an improved design to help address current lifter shortfalls for optimized molding productivity, including potential misalignment during the molding process, which can often lead to costly, unplanned production shutdowns, part quality problems and possibly catastrophic damage to the mold surface itself.

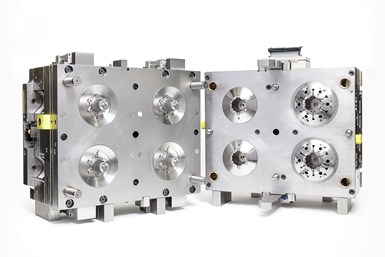

Edro Engineering and Specialty Steels Inc. showcases its specialization in the manufacture of high-cavitation custom mold bases, designed to demonstrate precision alignment and long-lasting performance. Edro primarily produces high-cavitation stripper molds, stack molds, super structures, spin-stack molds and hot runner bases, as well as auto unwind and runnerless mold bases to exacting tolerances.

Now offered in a Ø24-mm diameter, the CUMSA Sprue Adjuster (SA) family has been made available in 4 sizes. As with its smaller SA types, CUMSA says these sprue adjusters are offered in two versions—SA240022 and SA240822—which are suitable for molded parts which require larger runner gates, and are compatible with larger nozzle diameters up to 22 mm.

Hasco America’s proven range of plastic, aluminum and brass spiral cores has now been extended with the steel grade 1.4305. Specifically, the stainless steel spiral cores Z9611 (single-threaded version) and Z9612 (double-threaded version) are now available, and round off the company’s recently launched range of stainless steel cooling units.

Agathon Machine Tools now offers its new Guide System Plus, which performs guiding and centering tasks for the precise positioning of mold halves/mold component using only one system. Ideal for cleanroom, high-precision, micro-injection molding and high-temperature applications, the system is said to increase planning reliability in production, boost productivity and reduce overall production costs.

Cutting Tools

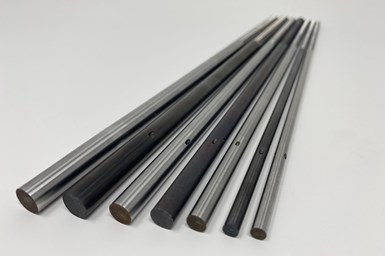

OSG has released a range of new end mill products, including the HY-PRO CARB VGM end mills and the A Brand AE-H advanced performance carbide end mill.

The HY-PRO CARB VGM variable end mill is a series of variable geometry end for dynamic milling, ideal in steel and stainless steel. Designed with unequal flute spacing, it reduces vibration during machining by altering the timing of each flute engaging in the work piece. The sharp rake angle, high helix and adjusted core diameter are said to maintain excellent cutting edge sharpness and tool rigidity which promotes smooth, stable cutting with low cutting force.

Seco Tools has expanded its line of square shoulder milling cutters with the Double Turbo, which includes the cutter and inserts. Utilizing double-sided ZOMX16 inserts with four cutting edges and Seco Tools milling grades, the cutters improve roughing operations and reduce power consumption in steel, stainless steels, cast iron and high-temperature alloys to meet the needs of job shops—like mold builders— and mass production facilities.

Walter’s new versatile Xtreme Evo DC160 Advance solid carbide drill is said to deliver exceptional productivity in a wide variety of materials, and a broad range of applications, which include the mold and die, energy, automotive, and general metalworking sectors.

Apart from the new 30 x Dc L/D ratio offering, the drill's design innovations include double margins and advanced placement of second margins that ensure better centering capabilities and the tendency of the drills to stabilize early into the cut. Walter says this gives an advantage in performing difficult applications such as cross holes and inclined entry and exits.

Allied Machine and Engineering highlights its high-penetration drilling system, the T-A Pro, a go-to solution that is said to take general purpose holemaking to a performance level previously unachievable by a spade insert.

The T-A Pro drill combines material-specific insert geometries, a redesigned drill body and a proprietary coolant-through system to allow penetration rates which the company says run at speeds nearly 30% faster than other high performance drills on the market.

Further extending the capabilities of high efficiency milling, Tungaloy America has expanded its MillQuadFeed high feed milling cutter series by adding new grades and cutter body options for its SWMT09 insert range.

According to the company, MillQuadFeed is a new generation of high feed milling cutters, offering two options of insert geometries that cover various high feed milling application needs.

Horn USA highlights its expanded tool range for high polish milling. The monocrystalline, diamond-tipped (MCD) ball nose end mills, intended for machining non-ferrous materials in the tool and moldmaking industries, save on polishing processes when producing free-form surfaces. Horn’s new offerings in large diameter variants are said to reduce machining time, guarantee compliance with the tightest tolerances and produce surface finishes in the nanometer range.

The YG-1 ENMX high-feed mill four is a new high-feed milling series developed to meet the most stringent demands of versatility, productivity and process stability for today’s applications. These types of tools are commonly used in mold and die, power generation and a variety of applications and materials in general machining markets.

Machining

Heidenhain debuts the EnDat 3 encoder interface protocol, which is said to offer users faster and more efficient machine motion control operation. The interface is available in the company’s ExI 1100 series of inductive rotary encoders. Heidenhain says the EnDat 3 preserves the features and benefits known to previous versions, while offering interface advancements.

Between the Mägerle MFP 30 5-axis grinding center’s ability to process complex geometries, the machine’s space-saving design and production-flow efficiency, United Grinding’s latest product is ideal for a versatile range of applications.

With a powerful 12,000-rpm spindle, the company says Mägerle MFP 30 enables shops to combine grinding processes, including creep feed grinding with corundum or grinding with CBN. The spindle delivers full performance and high torque even at low speeds, while robust tool-holding fixtures provide stability for wide contours as well as aggressive material removal rates.

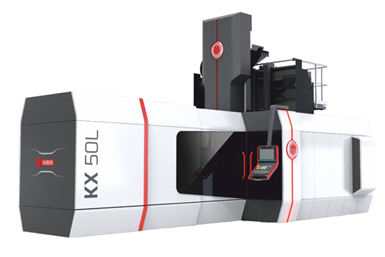

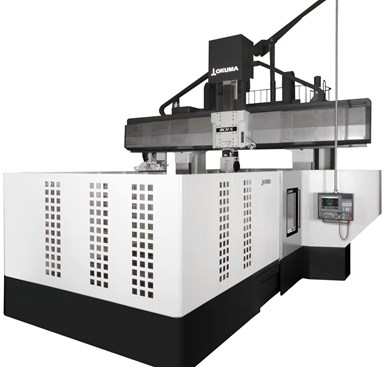

CNC machine tool manufacturer Okuma America Corp. debuts the MCR-S double column machining center (DCMC), which roughs and finishes press dies in one setup and is designed for heavy-duty machining of process-intensive press dies. It features full 5-face and 5-axis machining and is excellent for die repair work.

The MCR-S is also said to accommodate a wide range of stamping die requirements making it an ideal fit for the automotive and aerospace industries. It can easily handle hardened cast iron, nonferrous and exotic materials.

North American supplier of precision machine tools and automation, Methods Machine Tools, Inc., unveils its OKK VB53a vertical machining center (VMC) that is ideally suited for die and mold machining. The high-speed OKK VB53a features a range of features which minimize vibration and maximize accuracy, resulting in superior surface finishes for high-end die and mold applications, and precision parts.

According to GROB Systems, the company’s new Access Series five-axis machining centers are said to promise the best machining quality for individual and series production while offering cost-conscious entry into GROB technology. Featuring two U.S.-built basic models G350a and G550a, it is said these machines are also rated for optimized reliability, high productivity and modular expandability with automation solutions.

Inspection/Measurement

Takumi USA has partnered with Renishaw Inc. to be the first CNC machine tool brand to offer Renishaw’s Set and Inspect app for the Fanuc control. According to Takumi, Set and Inspect makes it possible for anyone with a part probe to add inspection probing to their process, enabling more efficiency and profitability to job shops of all sizes.

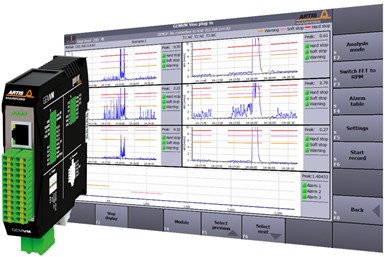

Marposs launches its Artis GEMGP stand-alone tool monitoring solution for detecting process anomalies during metal cutting in machine tools. Accommodating two sensors for measuring force and strain values obtained from the spindle during the machining process, the GEMGP is said to be able to detect and report on tool breakage, missing tools, overload, tool wear and fluid flow in real time which prevents damage to the machine, reduce scrap and improve productivity.

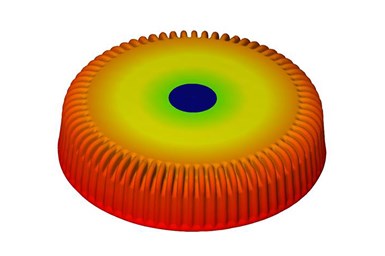

Exact Metrology performed a recent inspection on injection molded caps to showcase the capability of the GOM computed tomography (CT) scanner.

The scanner’s multi-part inspections capability enables the inspection of complex parts based on volume. It is said to produce the finest details visible throughout the component, simplifying initial sampling, tool correction and inspection tasks during production. Further, with its capabilities, it can capture complex components including the "inner workings" in a single scanning process, so that the user receives a complete image of the test specimen for form and position analysis or nominal/actual comparisons.

3D metrology company GOM GmbH developed the digital platform, HandsOnMetrology.com for companies that want to integrate the benefits of optical 3D metrology into quality control processes. From tutorials and how-tos and personal stories and insights from makers, to a global network that connects customers to companies selling 3D scanning products, GOM offers a comprehensive hub for interested manufacturers.

Zeiss Industrial Quality Solutions introduces its Zeiss AICell trace, a correlation-free measuring cell. A highly accurate shopfloor car body robotic process and quality control system, the cell achieves ISO 10360-8 stated accuracies while operating in extreme environments and offers what the company says is the industry's widest temperature operating range.

The L.S. Starrett Company relaunched its electronic hand tool line with the introduction of more than 100 electronic digital micrometers with new features for improved ergonomics, functionality and productivity for mold manufacture and maintenance. These electronic micrometers range from the No. 733.1 outside micrometers to a wide array of application-specific models, including a rounded anvil and tubular micrometer option that can be used to inspect mold walls and features such as hole-to-edge to verify specifications are being met.

Mold Maintenance, Repair and Surface Treatment

Alliance Specialties and Laser Sales is introducing its newest engraving system, the Leviathan. Said to match the versatility of its biblical namesake, the IPG Fiber Laser System is a free-standing, portable, completely open system, with 360-degree rotation and high flexibility. Built to handle larger, more functional work in critical areas, Alliance says its system provides greater accessibility to more difficult, harder-to-reach areas, and eliminates the deconstruction of a mold that would typically be sent out for repair or simple maintenance.

The Rocklin Manufacturing Co. MoldMender Micro Welder delivers simple and cost-effective mold and die repair in-house through a low heat, non-arcing welding process. Instead of sending molds out for repair or scrapping them prematurely, the MoldMender solves scratches, imperfections, pin holes, parting lines flashing and other mold and die imperfections with no welding experience necessary.

High Tech Laser & Polishing’s (HTL&P) wide range of services assist customers with mold surface repair projects while saving on shipping costs and lead times. The one-stop shop is ideal for laser welding, polishing and laser engraving amenities; HTL&P can laser weld mold components, blend down the weld and polish the area to match the existing surface. The core (shown above) is an example of a component High Tech has repaired.

The FiberStar Series manual laser welding systems for precision welding operations from LaserStar Technologies Corp. are ideal for a variety of common welding applications. This includes plastic injection mold, dies and tooling repair, complex electronic components, high-precision industrial assemblies, pressure-sensitive hermetic laser sealing and other industrial applications for the automotive, aerospace, aviation, medical device, mold repair and consumer product industries.

Millutensil offers a tool mover that can handle heavy molds easily and safely. Problems with conventional rotating and turning equipment include potential damage to expensive tools and damage to hoist brakes and ropes. The tool mover turns the load over at its center of gravity to ensure a smooth transition, minimizing the risk of damage to expensive molds or tools, as well as for the operator.

DW Sales has recently added three new fine grits—1,500, 2,000 and 3,000—to its Ceramic Super Stones range for semi-finishing, final finishing and mirror polishing. Available to the moldmaking industry for more than 20 years, DW Sales says Ceramic Super Stones are ideal for fine detail polishing. Strong and flexible, they are non-loading for use on all metals types, and are said to be thin enough for use in tight ribs and slots.

The Ultramax DF ultrasonic system from PCS Company is a dual-function unit that gives the versatility of both ultrasonic and mechanical polishing. Short stroke and fast reciprocation provides complete control over the most demanding polishing and deburring tasks. Control functions, such as an adjustable stroke length between 4-40 microns enable users to polish right up to the wall, or finish to an edge.

Made for moldmakers, mold maintenance technicians or anyone working with metal materials, Slide Products’ Copper Anti-Seize Compound is said to dramatically lower friction and torque between metal components, protecting against high heat and corrosion. Formulated with a higher amount of metallic solids than other compounds, it is heat stable up to 1,800ºF/982ºC.

Boride Engineered Abrasives adds Cristone end bristle brushes to its extensive offering of polishing products and accessories. Made from the same high-quality crystalline fibers as Cristone crystal fiber detail polishing stones, these end bristle brushes are ideal to use for cross hole deburring, surface finishing and polishing aircraft parts, engine blocks and medical devices.