Spray-Formed Steels Help Moldmakers Meet New Demands

Advances in spray-formed steels help moldmakers meet increased demands on production lifetime of molds and other machine tools.

The ever-increasing competition in the various manufacturing industries is causing more and more focus on more efficient and more economic production methods. One of the areas being analyzed is the production lifetime of molds and machine tools used in manufacturing operations. If the molds and tools could last longer, this would mean less costs due to fewer renewal tool purchases, fewer tool change operations due to wear, less tool renewal production downtime, less maintenance grinding and less maintenance costs.

At the same time, new materials and composites are being used in the production processes; in many cases, materials that are more abrasive—causing more wear on the molds and tools being used. Production managers are very aware of this and are looking for new ways of keeping wear to a minimum, thus keeping costs down. In both cases, investigating and using new types of materials with more wear resistance will help to meet these demands.

Spray-Formed Steel

Spray-formed steel is steel manufactured using a unique new process technology called the Osprey process. The steel is melted in a crucible using two induction furnaces and is then atomized in a spray chamber under a protected atmosphere. A specially designed spray head is used to deposit the semi-liquid steel onto a short cylindrical former (see Figure 1), which is simultaneously rotated and slowly moved in a direction parallel to the axis of the former. By carefully controlling the movements of the former and the spray parameters, it is possible today to manufacture cylindrical billets up to 550 mm in diameter and 2500 mm in length. The billets can afterwards be forged in order to obtain the dimensions needed

The advantage of spray forming is the high solidification speed of the liquid steel. This allows for a production of highly alloyed materials, which until today only have been possible with the powder metallurgy (PM) process. When using the spray forming process, the size of the wear-resistant carbides can be controlled in order to increase the wear resistance compared to a PM steel.

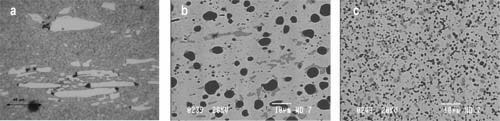

The photos shown in Figure 2 clearly illustrate the difference in the microstructure when traditionally cast steel (Figure 2a), spray-formed steel (Figure 2b) and PM materials (Figure 2c) are investigated under a microscope. The carbides in the traditionally cast steel are clustered in large strings and the sizes can be up to 100 µm in length. This can be a main reason for brittleness and this steel is often hardened to lower hardness in order not to lose too much ductility. The carbides in the traditionally cast steel are mainly formed by chromium, which has a hardness of approximately 1500 HV.

When spray forming steel or producing PM steel, the fast solidification of the steel enables the process to form very hard MC carbides, mainly based on vanadium, with hardness up to 2,950 HV. Furthermore, the spherical form of the carbides and the homogeneous distribution results in a more ductile material—giving the heat treatment shop the possibility of hardening the steel even more without losing the ductility. Carbide sizes are typically around 6 µm in spray-formed tool steels and below 3 µm in PM steel.

The main difference between spray-formed steel and PM steel is found in the number of process steps needed before the steel can be used. Using spray forming, the billets are produced from liquid metal in one step, whereas the PM billet has been through five to six expensive steps before hot forging can take place (see Figure 3). This results in spray-formed steel being less expensive than PM steel.

All this has been used in the development of two new steel alloys, which are to be used in high wear applications. One contains 8.9 percent Vanadium and is one of the most wear-resistant steel grades ever made. The other contains a little less Vanadium, 7.2 percent, but has a toughness of three to four times higher than the first.

Moldmaking Benefits

As a result of the spray-forming process, the steel itself shows some excellent properties. For one, it contains very hard primary carbides, which together with the nitrogen from the spray process increase the wear resistance of the steel. The process also ensures very clean steel due to the pouring and filtering method involved. Lastly, spray-formed steel shows excellent impact strength, compression strength and surface treatment properties compared to conventional tool steels.

Spray-formed steel has a very homogeneous structure, which secures even wear under usage, and allows for even machining during both the construction and maintenance phases. It also is completely free from macro-segregation (cracks) and in many cases even free from micro-segregation.

As an additional help to moldmakers, the spray-formed steel gives a higher form stability of the tool without the need for machining and stress annealing. Finally, the standard heat treatment procedures used for conventional steels can be used unchanged for spray-formed steels.

Using spray-formed steels gives additional benefits if the moldmaker also is the owner of the company he works in, the company then being a supplier to or subcontractor of larger companies where the molds are used in the production lines. These moldmaking companies will be able to supply molds made of the newest generation of steels with their unique properties, which in turn opens up for new potential customers. Additionally, they will be able to set a higher price level for tools and molds due to the superior steel properties.

Moldmaking Challenges

Steel Selection

One of the issues facing the moldmaker is choosing the right steel. In many cases the choice is made by the customer; however, in many other instances it is up to the moldmaker—Which alloy should I use? Which hardness? What about toughness?

Answers to these questions are often given by looking at the production process the molds are to be used in; the production material being handled by the mold, the lifetime requirements and many other factors. For example, the spray-formed steel allows for a better toughness, which creates the possibility for increasing hardness without compensation of toughness. But the moldmaker still needs to make the choice.

At this relatively early stage of spray-formed steel market penetration, the best suggestion is to contact some of the leading manufacturers for advice and help in selection of the right alloy and the right properties such as hardness and toughness.

Machining

Another issue is machining. As spray-formed steel typically is harder and tougher than conventional steel, the machining processes can be more difficult. At this relatively early stage of the spray-formed steel technology, it is hard to give general guidelines, but in a specific test case, machining costs were 25 percent higher than for conventional steel. However, in the same test case, the maintenance regrinding depth needed to refurbish the tools after use was only 0.1 mm for the spray-formed steel tool against 0.3 mm when using conventional steel. This is due to the more homogeneous structure of the spray-formed steel.

Application Cases

Spray-formed steel has been used in field tests as feed screws in extruding and injection molding processes. At a German company extruding PA reinforced with 45 percent glass fibers, spray-formed steel containing 8.9 percent Vanadium was used for the screw elements. After the test period, the spray-formed steel showed 27 to 49 percent less wear compared to 10 percent Vanadium PM alloy used previously. This corresponds to 35 percent longer tool life. The PM alloy was already far better than traditional cast steel with respect to tool lifetime.

When longer screws are needed, spray-formed steel with a higher toughness is a better choice. In a field test at an American company, the alloy with 7.2 percent Vanadium mentioned above was tested against a 9 percent Vanadium PM alloy. The test was carried out on feed screws used in an injection molding process for manufacturing plastic grinding wheels. The grinding wheels were made of a plastic reinforced with SiO2-particles. The feed screws were 50 to 80 mm in diameter and had a length of up to 2,500 mm.

After the test period, the spray-formed steel showed better lifetime figures than the 9 percent Vanadium PM alloy previously used. As a result, spray-formed steel is now being used as the standard steel for the feed screws at this American company.

As a final example, spray-formed steel was tested at an American company, which uses a small mold for steel powder compaction in order to produce a part used in the automotive industry. Using spray-formed steel with 8.9 percent Vanadium for the mold, 10 to 15,000 parts could be produced before the mold had to be taken out for regrinding due to wear. This contrasts vastly to the traditional cemented carbide used previously, where only three to 4,000 parts could be produced before maintenance regrinding was needed. The failure mechanism in this case was both chipping and wear. As an additional benefit to the moldmaker and the mold repair shop, machining turned out to be easier and the spray-formed steel mold was more easily polished than the traditional one.

Conclusion

Even at this early stage of spray-formed steel market penetration, a vast number of tests have proven that molds and tools made of spray-formed steel last longer and are more resistant to wear—meaning less costs due to fewer renewal tool purchases, fewer tool change operations due to wear, less tool renewal production downtime, less maintenance grinding and less maintenance costs. For the moldmaker, the steel shows excellent properties for mold construction and mold maintenance, even though machining in some cases may be more difficult. The biggest issue, however, is that the spray-formed steel is new to the moldmaker, so the best recommendation is to learn much more about this material of the future.

Read Next

Development of a New Mold Base Stainless Steel

Due to the intensive machining practices that must be performed on mold bases, if machining time and costs can be reduced, significant savings can be realized. A premuim free machining stainless holder steel has been developed that has optimized chemistry and processing, which lead to greatly improved machinability as well as other important properties.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More