Published

Software Manufacturers Reveal Moldmaking-Specific Offerings

There are some software manufacturers focusing on the moldmaking market, as reshoring efforts have stepped up—keeping two mold/die software manufacturers extremely busy. These exhibitors note that moldmakers are busier than ever—especially in automotive areas like Detroit.

There are some software manufacturers focusing on the moldmaking market, as reshoring efforts have stepped up—keeping two mold/die software manufacturers extremely busy. According to Kubotek USA’s (Booth E-3143) Marketing Communications Manager Andres Giles, moldmakers are busier than ever—especially in automotive areas like Detroit. “We have also seen that there is a lack of talent—moldmakers are looking to hire but able bodies are scarce. Because of this uneven supply and demand in the workforce, mold/tool and die shops are looking for ways to get more productivity, especially since their shops are running at capacity,” she states.

“These shops must still wait until projects are completed before getting paid,” Giles continues. “Terms can be as long as 12-18 months from OEMs. So even though they are busy, they don’t have a lot of money to spend on fancy PLM systems. They need practical yet complete CAD/CAM tools to get the job done.”

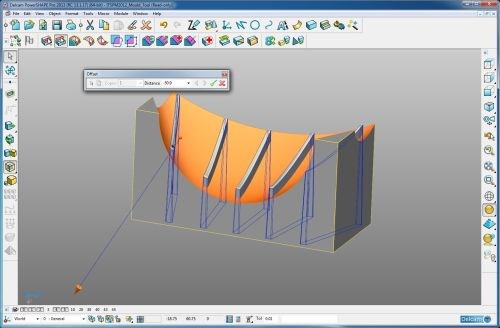

Peter Dickin, Marketing Manager at Delcam (Booth E-3222), expands on these sentiments. “We see customers that want better quality products delivered more quickly and at lower prices, and manufacturers that are adding more powerful equipment to meet these demands,” he says. “The good news is that business in North America is still growing, continuing the recovery from the downturn. Progressive companies are using this better business climate to invest, especially in high-speed and five-axis machine tools and the associated software to program this equipment.”

With moldmaking/tool and die comprising approximately 30 percent of Kubotek’s business, Giles notes that the company focused last year on listening to its customers’ needs. “We learned that they needed a way to quickly determine changes to a mold or tool design,” she says. “In response, we added Mold Tool and Die Specific functionality to KeyCreator and also our Kubotek Comparison Suite product KeyCreator Compare. This comparison functionality allows you to quickly compare two native CAD files—and the related product manufacturing information (PMI)—to quickly make the needed changes in the design and manufacture of the mold. It speeds time, reduces costs and allow manufacturers to complete Engineering Change Orders, keeping project on schedule and profitable.”

Kubotek will show KeyCreator CAD, KeyMachinist (a two- and three- axis fully integrated machining module for KeyCreator Direct CAD) and KeyCreator Compare (part of the Kubotek Comparison Suite) at its booth.

Dickin notes that moldmaking/tool and die comprises about half of Delcam’s business. The company will demonstrate its new integrated solution for electrode design, machining and inspection. “Despite the advances in high-speed machining, electrodes are still a key part of many toolmaking projects,” Dickin states.