Reshoring, For Sure

The Opening Keynote at the amerimold expo in Novi, MI, last week provided an update on the Reshoring Initiative founded by Harry Moser as well as some supporting data from Steve DeHoff of Stress Engineering Services. As a follow-up from the interest generated on this topic MMT and Harry Moser will be working on an article that involves readers customizing the TCO Estimator for molds. What we are looking for is a list of known factors that are not yet costed.

Share

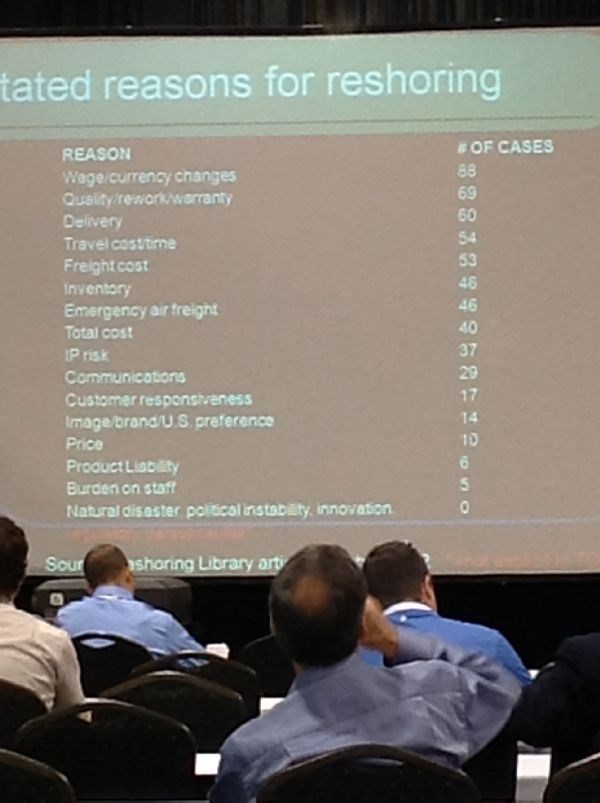

The Opening Keynote at the amerimold expo in Novi, MI, last week provided an update on the Reshoring Initiative founded by Harry Moser as well as some supporting data from Steve DeHoff of Stress Engineering Services. As a follow-up from the interest generated on this topic MMT and Harry Moser will be working on an article that involves readers customizing the TCO Estimator for molds. What we are looking for is a list of known factors that are not yet costed. We would also like to examine other factors including: formulas for calculating the factors; percentage of imported and domestic molds on which you see these issues; what each factor costs on the molds; where the factor occurs; and, cases of imported molds with these cost factors. The goal of this team effort is to develop a tool for the industry, so when it is completed, MMT will publish the results and let you provide feedback. Let me know if you are interested in participating.

I'd also like to include a special note from Jeff Lambing, Cost Estimating Software Sales Specialist for Perfect CalCard at JDL Technical Services and the manager of the Reshoring Initiative – bringing manufacturing jobs back home on LinkedIn:

"Strong interest in Reshoring at amerimold: There was steady traffic throughout the two-day amerimold event held in Novi, MI, on June 13 and 14. Having a booth and literature available there was a great way to help introduce reshoring to some, update others and generally just give many a chance to discuss. Harry Moser was well received at the opening keynote presentation along with Steve Dehoff, who gave some great case studies about the true cost of injection mold builds. It sure stirred a lot of conversation at the Reshoring booth later. Examples of Steve's case studies are on the AMBA website. We had several companies including two OEM's who expressed interest in having presentations done in their offices - so this could be a great opportunity to make some headway.

Congratulations to Tim Cahill of Rochling Automotive USA in SC in winning the draw for the newly released book by Karin Lindner 'How Can We Make Manufacturing Sexy - A mindset of passion and purpose from the production floor to the executive suite'.

A big thanks to Christina Fuges of MoldMaking Technology Magazine and Gardner Business Media for all they do in supporting the Reshoring Initiative. The same can be said for the many sponsors who have come on board to date as well."

And, thanks to you--Jeff, Harry and Steve!

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

U.S. Economy Indicates Prospects for Moldmakers

An examination of the U.S. economy suggests its resilience against a recession, yet a mixed outlook for moldmaking and plastics persists.

-

How to Successfully Reshore Tooling

Sloan Valve and Pyramid Molding Group shed light on the dynamics and challenges surrounding the shift toward domestic mold sourcing and the advantages of collaborating with a U.S. supplier to bring tooling back stateside.