German moldmaker and hot runner specialist Männer presents its new micro injection molding system micro-män for the first time in the USA. The production cell promises users custom solutions for the production of microparts and small parts. micro-män is a single-machine solution designed to cover a wide range of applications in high-precision injection molding (Figure 1). To demonstrate micro-män’s flexibility, Männer will be producing two different gears of a planetary gear system in a single production run – live at NPE.

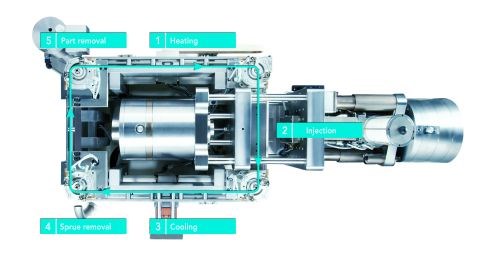

The fundamental processes in injection molding like heating of the mold, injection, cooling, and part removal must be performed sequentially with conventional injection molding machines. micro-män, however, is different. Here, multiple process steps are carried out simultaneously (Figure 2). The reason for this can be found in the machine concept: the mold half carrying a molded part does not remain as usual in the closing unit, but instead is conveyed to various process modules by means of a transposition system. When multiple hot halves are used, one mold half can be heated while, simultaneously, a second one is cooled, the part is removed from a third one, and resin is injected into the fourth. The parallel execution of processes results in an increased frequency rate, saving valuable production time.

This concept is responsible for the real strength of micro-män when dealing with special applications. The basic model can be easily equipped to handle special applications – for insertion and overmolding, for rapid and frequent color changes, for part magnetization, for multicomponents, and much more. Additional modules such as handling systems or video cameras for quality monitoring or other purposes can be directly integrated into the transposition system.

The innovative micro-män concept can turn the production of even small quantities or an initial series into a cost-effective undertaking.

The compact production cell is self-contained, clean, quiet, easy to transport, and quickly operational. It can be set up anywhere without special effort and is operational within 15 minutes. micro-män can even be integrated into an assembly line.

micro-män is the subject of internationally pending patent applications.

Contact

männer Solutions for Plastics

Eveline Geppert

Unter Gereuth 9-11

79353 Bahlingen a. K.

Germany

Phone +49 (0) 7663 609-0

Fax +49 (0) 7663 609-299

presse@maenner-group.com

männer – Solutions for Plastics:

We develop and manufacture product solutions for injection molding applications. Leading companies in the pharmaceutical / medical technology, packaging, and personal care industries produce their innovative plastic products using high-precision molds and valve gate systems by männer. männer’s Micro Molding Systems business division specializes in the manufacture of microparts and miniparts. With around 380 employees worldwide, männer is among the industry's leading suppliers. männer has its own production, sales, and service locations in Europe, the USA, and Asia.

Live in Orlando: Production of Different Gears of a Planetary Gear System in a Single Production Cycle

NPE, April 1 – 5, 2012, in Orlando: West Hall A, Booth 163