New Technology?

New does not really mean “new” – right?

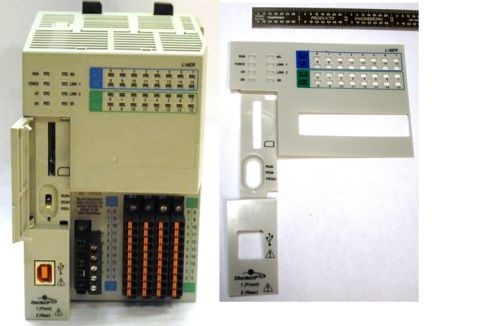

For example, we are working with a customer who was having issues with pad printed details being washed away after years of industrial use including: chemical splash, harsh detergent washing, UV fade, and just generally sitting in an exposed environment. While these products are not for consumers they still need to perform and maintain all printed characteristics as when new – most of the time 10 to 20 years later.

This is where we introduced “new” technology to them; In-Mold-Labeling (IML). Ok, ok, I can hear you groaning now… “what is so new about IML?”. Well, to some, nothing. You have been using it successfully for many years. So why the “new”? To this customer it was new. New to their product and new to their company. As the program moved successfully forward word got out. As word spread more engineers were asking about this “new” technology and how could they incorporate into their products. As with anything, “new “ is not the answer to everything, especially as you balance cost and practicality with needs, but sometimes “old” is “new” – just like some of us who have been around forever! So when presented with challenges remember, there is a great deal of technology yet to be developed, but the existing technology library can still be your best resource for new applications!