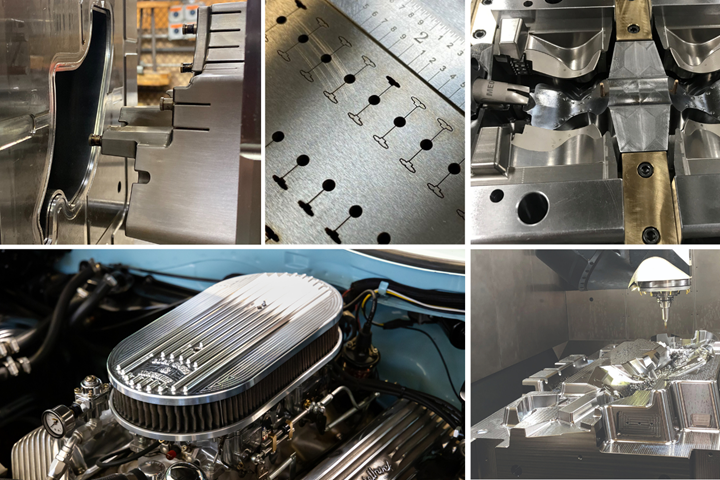

The MoldMaking Technology team has compiled this top five list for the month of January. Based on the analytics for items published the last 30 days, these are MMT’s most popular articles. Check out these great pieces on design, metal additive manufacturing, hot rods and more.

Check out the most popular items from this past month.

1. Shared Engineering Expertise Overcomes Design and Delivery Challenges

Collaboration on part and mold design between a molder and mold builder were vital to overcoming design and production challenges for a unique automotive project.

2. How to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

3. How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

4. Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

5. Diversification and Departmentalization Drive Growth for Wisconsin Mold Builder

New ownership at Innovation Mold & Design (IMD) grows the company by investment in technology that serves a departmentalization and diversification, business model.

MoldMaking Technology is here to bring you what’s new and what works in moldmaking. Not subscribed to MoldMaking Technology Magazine? Get it in either your mailbox or inbox for free.

Thank you all for your constant support of MoldMaking Technology. We are so glad to have you as a part of our community.

Related Content

-

Mold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

-

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.