10. Perspectives on Sustainability in Mold Building: A Diverse Outlook

In conversations Editorial Director, Christina Fuges, recently had with individuals involved in the mold building industry, a variety of perspectives on sustainability emerged, showcasing the multifaceted nature of the term. This article is a summary of the respondents’ viewpoints.

8. Editorial Advisory Board 2023-2026: Corey Alton Fox, Accede Mold & Tool

Source: Accede Mold & Tool

Introducing new editorial advisory board (EAB) member, Corey Alton Fox. Corey is a third-generation leader in the moldmaking industry and a seasoned professional in his own right. He is currently the operations manager at Accede Mold & Tool, an independent and privately-owned injection mold builder in Rochester, New York. Learn more about Corey.

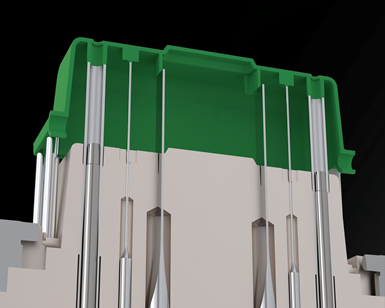

6. Extensive Evaluations Build The Plastek Group’s EDM Arsenal

Source: The Plastek Group

The Plastek Group is a moldmaker and custom injection molder with facilities in Erie, Pennsylvania, Hamlet, North Carolina, Queretaro, Mexico, Indaiatuba, Brazil and Mansfield, U.K. The company produces tools in Erie and Indaiatuba, makes engineering changes in Erie, and molds in Hamlet and Mansfield. All facilities offer mold maintenance and repair. As part of an ambitious 5-year plan for equipment upgrades and replacements, in 2022, they decided to swap out all EDM equipment at one of its two moldmaking facilities in Erie. This case study details their process in choosing a supplier for their new EDM equipment.

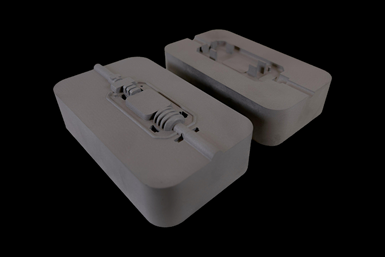

4. Mold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Source: Westminster Tool

Since July 2022, Class 101 injection mold manufacturer—Westminster Tool —has been on a relentless journey with Mantle Beta metal additive manufacturing (AM) technology. Through extensive trials and collaborations with Mantle, they've optimized quality and efficiency. Read about their latest success story which involved rapidly producing production-grade parts for a medical OEM's biocompatibility and functional tests using metal 3D printing.

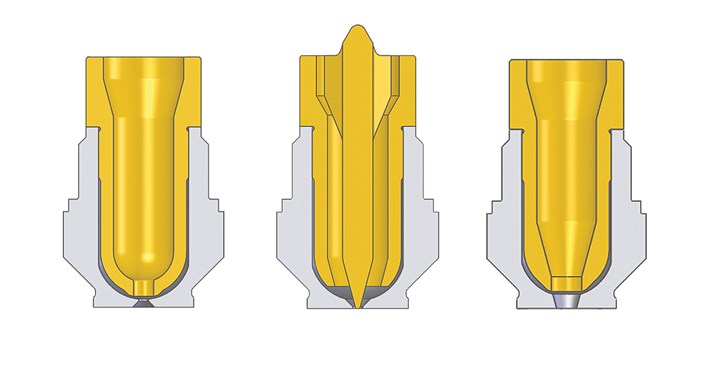

2. Ejector Pin Selection Guide

To perform optimally, ejector pins must possess certain fundamental characteristics, including a high degree of strength, toughness and wear resistance, and the ability to retain edges. More application-specific characteristics include hot hardness, which is the material's ability to retain hardness at elevated temperatures, and varying degrees of corrosion resistance and lubricity, depending upon the type of molding application. Take a look at PCS Company’s comprehensive selection guide.

Read Next

New Year, New Popular Articles from MoldMaking Technology

The top ten most-viewed articles in January reflected not only what our readers wanted to see—but also what is new and trending in moldmaking.

Read MoreMoldMaking Technology's Best of November

From 3D scanning to machine monitoring and everything in between, here are the top 10 most-viewed articles from November based on Google Analytics.

Read MoreMoldMaking Technology's Most-Viewed MMT Chats of 2023

MMT Chats—hosted by Christina Fuges—is a conversational video series uniting moldmaking professionalss to talk about manufacturing, tooling, and moldmaking methods. Take a look at our top five most-viewed MMT Chats based on Google Analytics.

Read More