Mastering Micro-TIG Welding

Successfully meeting customer expectations for micro-TIG welding mold repair demands a certain level of knowledge and technique.

The most critical concern for customers when it comes to mold repair today is quality. If a customer has parts repaired and then within a short time period those same parts are in need of repair again, it not only reflects poorly upon the welder, now the customer is stuck spending more money and time having those same parts repaired for a second time. This causes a lot of aggravation, resentment, and quite possibly the loss of that customer.

Mold repair entails some form of welding, and micro-TIG welding has been losing popularity due to the recent prominence of laser welding. The reason is because micro-TIG requires years of practice before one can master the process consistently to produce acceptable quality results and readily solve problems that occur during the welding process. Laser welding, on the other hand, has a shorter learning curve, which has fueled its increased usage in manufacturing today.

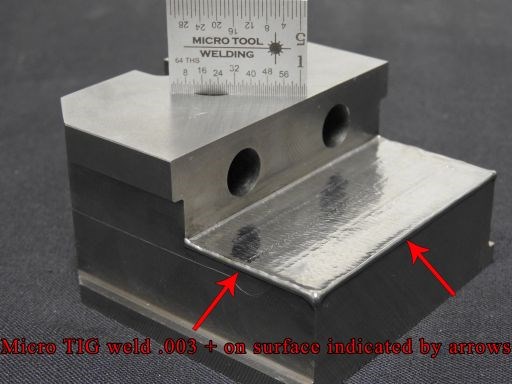

Both processes have their place in today’s modern mold shops, but with customers continuing to increase their focus on quality, turnaround time and cost, employing micro TIG welding effectively requires a certain level of experience because it employs very small wire and a very tight arc gap, which requires very low amperage and keeping the electrode very close to the workpiece.

Micro-TIG welders need a solid understanding of metallurgy, heat treatment (pre and post heating), welding wire, welding rod material properties and the different techniques used for a wide variety of tool steels. This is because tool steels require specific preheating and post heating temperatures.

Turn-around time ranks a close second in importance to quality because the customer is basically losing money while parts are out for repair. Production cannot proceed until repaired parts are returned. Micro-TIG welding offers speedy turn-around time, but again it all depends on a competent operator. An experienced micro-TIG welder knows how the welding process will affect the expected results and can utilize best practices to achieve them.

Experience also plays a part in cost, which is the third greatest customer concern. If you have acquired helpful micro TIG welding techniques over the years, you will be able to save time and money for your customer. Also, if you are capable of employing different strategies that can save the customer time and money, those customers will be more likely to return to your company for their welding needs. And, the sooner you finish repairing parts for one customer, the sooner you can begin working on other customers’ parts. It’s a win-win.

Related Content

-

What You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.