Integrating NVD Into Moldmaking

Nickel vapor deposition technology in the moldmaking process allows for durable molds, corrosion resistance and shorter cycle times.

Moldmakers are constantly challenged by their customers to evaluate new technologies that can be integrated into their mold builds. Through reduced cycle times, shorter deliveries, lighter weight, better durability and corrosion resistance, moldmakers need to find new and different ways of improving the mold building process. With its nickel vapor deposition (NVD) technology, Weber Manufacturing (Midland, ON) offered DuPont (Wilmington, DE)Ña worldwide company involved in developing products and services for the consumer, aerospace and medical industriesÑthe chance to make all these challenges possible.

Origins

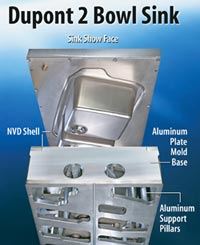

The original molds built for the DuPont Corian¨ sinks were conventional, multicavity designs machined from solid aluminum blocks (see DuPont Sinks sidebar). The heating of the molds was accomplished by flooding water onto the back of the mold halves after the cavity has been filled. Cycle times and costs had to be reduced.

The molding process also required the mold design to include a flash geometry around the product, due to the follow-up compression action of the mold to accommodate significant material shrinkage. After de-molding, a significant amount of post-processing was required. The individual parts had to be separated, de-flashed, de-gated, CNC machined and hand finished.

John Hannon, the senior research engineer at DuPont, who is responsible for the shape line, was first introduced to vapor-deposited nickel shells at a molding conference. John contacted Rob Sheppard, general manager of Weber Manufacturing's Nickel Tooling Technology (NTT) Division and outlined the challenge.

"We both saw a perfect fit for our NVD technology with DuPont's mold requirements," says Sheppard, "we wanted to replace relatively soft, 13-inch thick aluminum molds with 38-42Rc hard, 5/16-inch thick, solid nickel shell molds as a way to increase production, increase quality and reduce costs." (see Aluminum Versus Solid Nickel Shell Molds sidebar, page 46.)

NVD Technology

Weber's NVD technology basically converts a nickel carbonyl (NiCO4) vapor into a solid, metallic nickel shell by depositing it in a specially designed chamber onto a heated substrate (the mandrel). Mandrels are the negative of the mold face and can be made of any clean, thermally conductive metal (typically aluminum or steel). Weber CNC machines the mandrels on state-of-the-art, five-axis machining centers from engineering designs generated in IDEAS and CATIA. The mandrels are completely reusable for multiple mold requirements; so the machining is only done once, providing significant savings in cost and time for subsequent molds.

The NVD process is extremely fast, 0.010 in/hour, producing a solid, 99.9 percent pure nickel shell atom-by-atom on the mandrel surface. It reproduces the mandrel surface exactly, down to the micron level, and the resultant shell is as accurate as the mandrel. Thermally, nickel has conductivity more than twice that of P20 and because the thin shell has significantly less mass than a conventional aluminum mold, transfers heat to and from the moldface as well or better than aluminum.

The Process

As a first step, Weber built a single 29.5 x 21 inch prototype nickel shell mold. DuPont inserted this mold into its production line. The nickel shell mold design is flood heated and cooled from the back. The water delivery system did not need to be altered to accommodate the change from aluminum to nickel shells, allowing a direct performance comparison. While some reductions in cycle time were noted, at this point the hard NVD nickel surface was the convincing benefit for John and the DuPont production staff.

The success of the prototype led to a multicell nickel shell mold production order for a combination of multiple identical molds, for a variety of seven different sink designs. The complete replacement of aluminum molds with similar nickel shell molds would allow the system to achieve cycle time reductions.

Additional Opportunities

DuPont saw yet another opportunity with this technology. Net molding of sinks could eliminate all post mold machining and polishing operations. Hannon and Tom Schmitz, NTT's engineering manager, led a team from both companies. They first developed an innovative seal-off geometry that would provide a smooth, net edge for both the part and any molded holes. Cores and cavities, designed with this new geometry were made with 5/16-inch thick NVD nickel shells. The shells were mounted to a welded aluminum support frame and supported from behind in critical areas. Features for alignment bushings, mounting locators and bolt counter bores were machined in the mandrel and thus directly encapsulated into the nickel shell.

A second NVD nickel shell tool was put into production and proved to have the strength to include the features that made net molding feasible. These features allowed for the easy separation between product and flash and knocking out of the drain hole. The mold design was then incorporated into a product family of seven different shapes.

The success was dramatic. DuPont was able to completely eliminate post mold machining and sell off its six CNC routers. Damage from handling and transportation was eliminated and inventory reduced, since no sinks were waiting for subsequent operations or movement. The durable nickel surface eliminated mold dings and serious damage could easily be weld repaired. Hand finishing personnel were reassigned to packaging and shipping. Cycle times from melt to box (from molding to shipping) were cut in half.

Weber allowed the facility to keep up with demand, without expanding the facility. Hannon explains, "As the business grew, we literally could not keep up without the change in mold design using NVD nickel shells."

When considering NVD technology, moldmakers should evaluate what impact all or some of the benefits noted could have on the overall mold build (see NVD Benefits to the Moldmaker sidebar). Find new and different ways of improving the process by first considering the economical and technical benefits of potential applications.

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

A Low-Tech Solution for Cutting Moldmaking Costs

Machine-ready blanks have been available for decades, yet mold manufacturers have been slow to adopt them, even though they can save as much as 30 percent off overall mold and mold component costs and free up machine time for creating more in-house capacity.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More