Energy/Power Generation Outlook

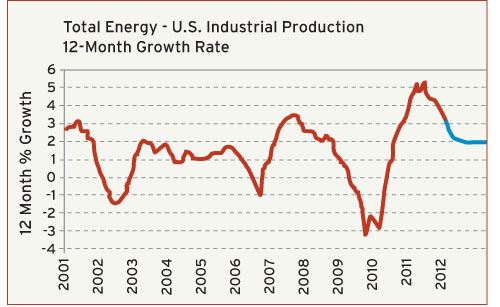

After a decline of nearly 3% during the Great Recession of 2009, total U.S. output of energy and power products enjoyed above average growth in both 2010 and 2011. At the present time, America is generating more power and producing more energy products than ever before. We expect this growth trend to continue in 2012, but the growth rate will settle down closer to the long-term average of about 2% this year. This forecast is based on expectations of moderate overall growth in the U.S. economy, which would be in the range of 2.5%-3.0% for the year.

Demand for electricity will continue to rise for the foreseeable future due primarily to the trend of rising demand for electronics products by both consumers and businesses. There will also be accelerating growth in demand for electric vehicles. Recent expansion in the capacity to generate electricity by traditional means has struggled to keep pace with this rising demand, and this has put premium on alternative ways to generate power (solar, wind, geothermal, etc.) and also on products that enhance efficiency. These efficiency gains are being realized by new types of appliances and machinery, and also by upgrades to the distribution system (think smartgrid).

Another energy trend that will gain momentum in the coming years is the increased substitution of natural gas for crude oil and its derivatives. The global market prices for crude oil and natural gas used to correlate strongly, but this relationship has diverged widely in North America in recent years. The good news is that not only is natural gas cheaper, but it is also cleaner and relatively abundant in this country. Look for a steady rise in demand for appliances and machinery that utilize natural gas as a fuel. This means there will also be a rise in the products used for the production, storage and distribution of natural gas in the coming years.

Computer Industry Outlook

It is difficult to think of a sector of the global economy that has a brighter long-term outlook than the computer and electronics industries. This statement holds true for all of the various segments of the electronics sector. Global output and sales of electronic products for computers, audio/visual, telecommunications, industrial uses, commercial uses, defense uses, medical devices, transportation, security devices, construction and energy generation are all expected to increase at an average annual rate of at least 5% for the foreseeable future.

And rest assured that U.S. manufacturers of computer products will benefit greatly from this global uptrend. The Fed compiles and reports a monthly index of the total U.S. production of computers and peripheral products. The chart is a graph of the 12-month growth rate for this monthly data. Like most segments of the manufacturing sector, the computer industry is vulnerable to recessions in the U.S. economy. Hence, the negative growth rates in the years 2002 and 2009. But what is most interesting is both the speed with which this industry recovers after a recession and also the high rates of growth this industry enjoys during periods of economic expansion.

In 2010, the total U.S. output of computer products surpassed its pre-recession peak, and then it grew by more than 7% in 2011. Our forecast calls for a gain of at least another 5% in 2012. This forecast is based on our expectations that the current recovery in the U.S. economy will continue to improve gradually. We are also factoring in a moderate recession in the European economy during the first half 2012 followed by slow growth during the second half of this year.

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More