Ed Partnership Lays Ground for Cultivating Ind Maintenance Workforce

The National Institute for Metalworking Skills (NIMS) has formed an educational partnership with Lightweight Innovations for Tomorrow (LIFT) – one of the new national manufacturing innovation institutes -- and Ivy Tech Community College in Indiana to train community and technical college instructors, as well as industry trainers, in industrial technology maintenance (ITM).

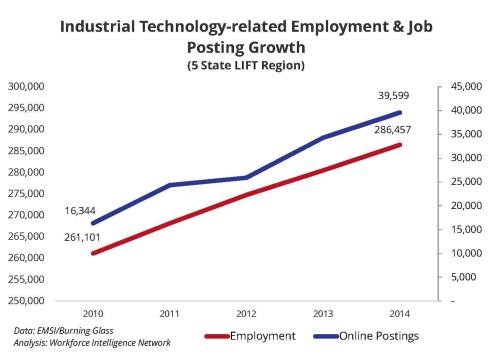

The National Institute for Metalworking Skills (NIMS) has formed an educational partnership with Lightweight Innovations for Tomorrow (LIFT) – one of the new national manufacturing innovation institutes -- and Ivy Tech Community College in Indiana to train community and technical college instructors, as well as industry trainers, in industrial technology maintenance (ITM). The program is part of a comprehensive effort to prepare a new industrial technology maintenance workforce, which drives the performance and improvement of high-tech manufacturing, and has grown in demand by 118% from 2011 to 2015 in Indiana, Kentucky, Michigan, Ohio, and Tennessee.

“In 2015, there were over 53,000 industrial technology maintenance jobs posted in the region,” said Larry Brown, executive director, LIFT. “Our manufacturers depend on skilled workers in these jobs to support productive manufacturing and integrate the latest technologies into company processes and maintain their performance over time.”

A LIFT high demand skill profile reports that demand is particularly strong for companies in the automotive, aviation/aerospace, rail, ship and heavy truck industries, which are highly concentrated geographically within the I-75 corridor. Industrial technology maintenance skills entail the maintenance, troubleshooting and improvement of complex machines and automated systems used in today’s advanced manufacturing environments.

The components of the NIMS, LIFT and Ivy Tech partnership include: rolling out the first-ever industry standards for educating and training the industrial technology maintenance workforce; developing nationally-portable, industry-recognized skills credentials based on these standards; training instructors from community colleges across the entire region; and equipping a competent workforce with the knowledge, skills and credentials they need to enter into and advance in the field.

Ivy Tech and NIMS have collaborated to launch the ITM workshop series to train instructors—in both educational institutions and company training programs—on how to implement the industrial technology maintenance industry standards into curriculum and deliver the related NIMS credentials to their students. Workshops are scheduled for March 21-23, 2016, and April 18-20, 2016. Interested instructors can sign up here.

The lack of skilled workers in manufacturing is much more far-reaching than what the moldmaking industry faces. It’s going to take time to fill the void that aging skilled workers will leave as they retire. This partnership will hopefully become successful and serve as a role model for future programs of similar scope. As these organizations ramp up training of instructors so they can begin to train their students, the rest of us must ramp up some excitement about career opportunities in our fields so that there are students to learn these skills.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.