Design Out the Effects of Gravity with Mold Orientation

Gravity will have very little influence over the majority of injection-molded plastic parts, but under the right conditions, it can certainly alter the filling of a mold and the resultant part quality.

Gravity will have very little influence over the majority of injection-molded plastic parts, and its effect can be ignored. However, under the right conditions, gravity can certainly alter the filling of a mold and the resultant part quality. A mold designer for thick-walled parts may want to keep this in mind as cavity orientations are determined. Otherwise, the molder may unnecessarily find himself chasing his tail.

Are plastic materials immune to Isaac Newton’s Law of Universal Gravitation? No. Then why is it considered absurd to think that gravity could not influence the filling of a plastic part made by the injection molding process? The simple answer is that gravity always acts on the material, but its influence is heavily affected by wall thickness.

A majority of plastic parts are considered thin-walled. In this situation, the relatively thin-walled channels, high-viscosity fluid and high-pressure-driven flow assures that the plastic is nearly always in intimate contact with the cavity walls. This intimate contact causes the polymer to freeze/stick to the cavity walls. Couple that with the fact that the molding process is done under very high speeds and pressures, and we simply don’t expect to see much influence, or at least any measurable amount of influence, of the gravitational pull on the majority of molded parts.

However, there are molders who make plastic parts that have thick wall sections. And depending on the wall thickness, material being molded, process conditions, cavity orientation, gate location and a few other factors, gravity may finally have a chance to work its magic on our plastic parts. After all, if there is nothing for the plastic to stick to as it comes out of the gate, then the plastic will fall to the bottom of the cavity.

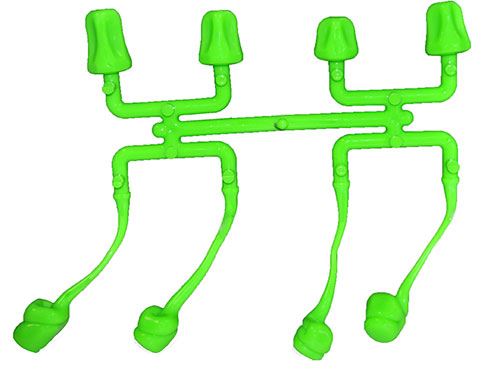

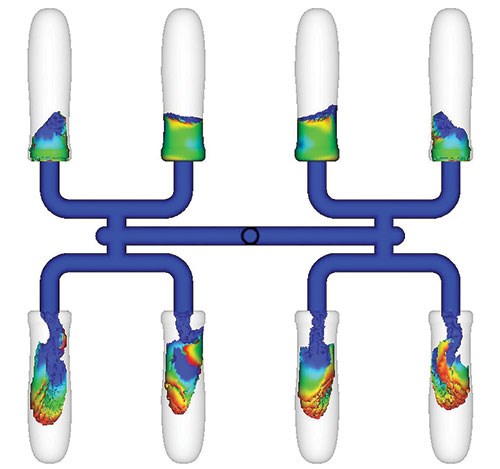

Take, for example, a mold producing thick-walled screwdriver handles. The short shot in Figure 1 shows how gravity pulled the plastic to the bottom of the four cavities, thus causing a cosmetic defect in those four cavities. The top four cavities filled as expected with no cosmetic defects present. This filling pattern was also observed in the filling simulation that was set up to consider gravity effects in its calculations (see Figure 2). The mold was then turned 90 degrees and, after the laughter turned to amazement, the problem went away. Note that not all gravity-related molding issues can be solved by simply turning the mold 90 degrees. This may only move the problem to different cavities. For thick-walled parts, cavity orientation must be considered during the mold design phase to reduce the chance of problems down the road.