Attract New Customers with Full Product Development Solutions

One mold builder dramatically increased its ability to move fast and help customers get product to market in the shortest amount of time by applying its mold leadtime reduction principles to its product development processes.

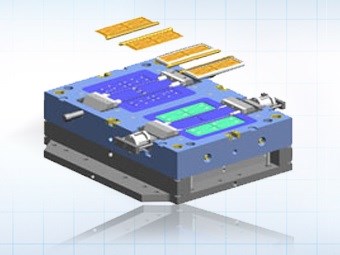

MME group was founded in 1974 as a tool and die shop in St. Paul, Minn. Twenty years later, and before taking on production molding, the company discovered that short leadtimes for new tooling was a key component of the entire new product development process. The company became a leading tool shops in the Midwest by reducing the typical industry tool construction leadtime from 12 weeks to an average of four. They then applied those same principles for reducing mold building leadtimes to product development, which has helped them get their customers' products to commercialization fast.

Related Content

-

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

-

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

-

Confronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.