Maintain

Scatter Correction CT Addresses X-ray Scatter Artifacts in Industrial Scanning

Nikon announces the launch of Scatter Correction CT, a software solution that enhances image quality and measurement accuracy in industrial computed tomography (CT) scanning by correcting scatter artifacts.

Read MoreLaser Cleaner Minimizes Mold Cleaning Risks

Rocklin Manufacturing Co.’s LC/RR 1500 Laser Cleaner offers a simple, fast and precise alternative to minimize mold cleaning risks.

Read MoreLaser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved their tool room efficiency when it comes to difficult welds and urgent repairs.

Read MoreBest Practices for Engraving Cores and Cavities

Consider depth, font style, artwork size, polarity and location when engraving.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

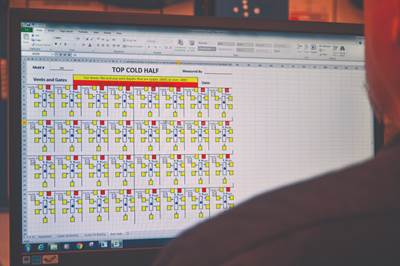

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

WatchWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read More7 Measurement Innovations Transforming Moldmaking

Smart sensors and sophisticated process and measurement data management are driving intelligent moldmaking to new heights.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read More

.jpg;maxWidth=300;quality=90)