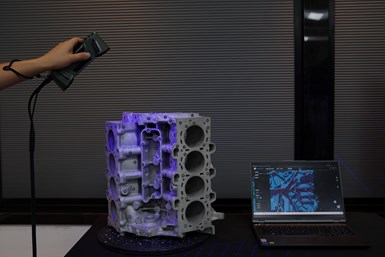

Dual-Mode Metrology Scanner for Accurate Mold Measuring

The highly ergonomic and compact FreeScan Combo from Shining 3D adopts metrology-grade accuracy, fine scanning and high precision for inspection and reverse engineering.

Shining 3D, a global provider of technologies for 3D digitization and 3D inspection, expands its FreeScan UE series of metrology 3D scanners with the FreeScan Combo. Increasingly, noncontact 3D inspection has become a go-to method for moldmakers as free-form surfaces increase and the precision requirements for mold processing rise.

FreeScan Combo adopts metrology-grade accuracy, fine scanning and high precision from the FreeScan series, while providing an even lighter and more compact design. It features 26 + 7 + 1 blue laser lines and an infrared scanning mode. Considering speed, versatility and accuracy, this high-performance 3D metrology solution is said to meet the needs of different scanning scenarios such as metrology-grade inspection, reverse engineering and further applications.

The FreeScan Combo can achieve a scanning speed of 1,860,000 points per second using the laser scan mode and a speed of 2,250,000 points per second utilizing infrared mode, according to the company. FreeScan Combo delivers high accuracy according to VDI-VDE 2634-2 of 0.02 mm while capturing a large amount of data per second.

Different scanning modes available include: 26 laser lines suitable for easy and large size laser scanning; 7 parallel laser lines for scanning fine details; 1 laser line to obtain 3D data from narrow areas such as holes; and an infrared mode which can scan without markers.

FreeScan Combo also provides an easy workflow, powerful and user-friendly software. The software integrates connections to the more commonly used 3D inspection and design software, enabling the scan data to be imported more efficiently.

These features are all fit into an ergonomic and compact design, with a size of 193 × 63 × 53 mm and a weight of 620 g.

Related Content

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

.jpg;maxWidth=300;quality=90)