Industry 40

Automation and Moldmaking: Mold Production in Action

Moldmakers are starting to change the way they think and incorporate automation into all aspects of their operation—combining a multitude of processes in a single cell for optimal productivity.

Read MoreProcess Management Leads to Easier Automation

Before you move your shop into full blown automation, integrate a pallet system and process management software.

Read MoreMolding Success Through Automation

HSM technology helps U.S. moldmaker maintain world-class productivity and business growth.

Read MoreInvestments in Productivity: Automation Integration In the Toolroom

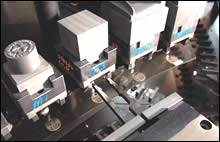

By integrating machining, workpiece and cutting tool management, CMM verification, and a Web-based video and control system, a completely integrated cell producing fully qualified electrodes through automated manufacturing can be created.

Read MoreAutomation

EROWA Technology (Arlington Heights, IL) will highlight its many automation solutions.

Read MoreThe Center of Automation

Macro pallet-mounted gage balls reduce overall costs in electrode machining/manufacturing and reduce leadtime by 25 percent.

Read MoreAutomation Increases Throughput

The addition of an automated cell helps moldmaker/prototyper increase efficiency and speed.

Read MoreM&M Tool and Mold: Formula for Success-Specialization, Automation And Customer Service

The third times a charm for this specialty mold shop that yields complex molds in tight leadtimes as it snags MoldMaking Technology's 2005 Leadtime Leader: Small Shop award three years running.

Read MoreThe Race to EDM Automation

In order for moldmakers to compete with overseas forces and their huge labor cost advantages, automation is no longer an option...it is a necessity.

Read MoreClosing the Automation Loop

By using self-correcting manufacturing, moldmakers can maintain their competitive edge and continue to reduce the labor component in their products.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)