Industry 40

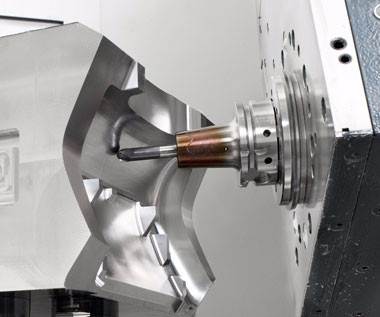

Milling and EDM Automation Reshape Summit Tooling’s Mold Operations

Summit Tooling President Dan Martin credits the capability to run unattended machining 24/7 to the partnership that his company built with Makino.

WatchAutomation and AM Help W. Fassnacht Werkzeug- und Formenbau Win Germany’s 2017 Toolmaker of the Year Title

Germany’s Toolmaker of the Year 2017 does things small but in a smart way when it comes to the design and manufacture of multi-component molds, in-mold-labeling and tools with integrated assembly functions.

Read MoreTechnology Tuesday: Automation Fuels Productivity

Cruise through this week’s Technology Tuesday blog to see ways in which automation is boosting productivity and efficiency in moldmaking.

Read MorePower of the Cloud and IIoT Makes Manufacturing Smarter

Democratizing factory management in the age of design and manufacturing convergence.

Read MoreRealizing EDM's Full Potential with Automation

EMO Hannover 2017 was a showcase for EDM developments, automation solutions and software for data-driven manufacturing.

Read MorePre-Machining Best Practices for Industry 4.0

Emphasis on technology that streamlines processes and provides repeatable outputs in your machining operations is key to automation and data-driven intelligence. Here are some common pre- and in-process attributes to consider as they pertain to process efficiency and reliability.

Read MoreTechnology Tuesday: EMO Wrap Up on EDM, Automation and Industry 4.0

EMO Hannover 2017 was a showcase for EDM developments, automation solutions and software for data-driven manufacturing. EDM technology is evolving through new machine designs, thermal stability, powerful generators, parts handling robots, linear handling systems and software solutions for future Industry 4.0 infrastructures.

WatchInvest Now in Die/Mold Automation to Meet Growing Customer Demand

In today’s highly competitive global marketplace, there are two types of mold shop owners, (1) those who invest in new technology and automation to create innovative ways to meet customer demands for shorter lead times, more complex designs and tighter tolerances and (2) those show don’t invest and quickly fall behind other North American shops and low-cost, offshore manufacturers. Here is a case study from Makino about one mold builder who fits nicely into type number one.

Read MoreSLIDEHOW: Process Automation and Planning Strategies

I sometimes forget that many technology suppliers to the moldmaking industry are also manufacturers that use many of the same products and equipment that you do, while facing similar challenges. For example, last month during the K Show in Germany I had the opportunity to visit Hasco’s corporate headquarters in Ludenscheid.

Read MoreAn Industry 4.0 Proving Ground

By making use of data collected directly from its machines, this mold manufacturer is riding the wave to the next industrial revolution.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)