Industry 40

A Blueprint for Die-Mold Shop Automation

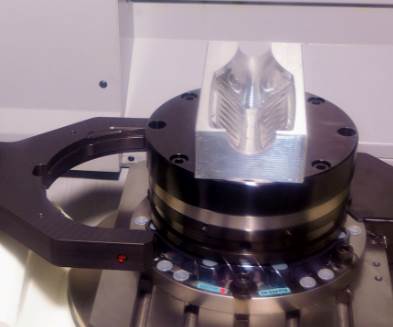

An increasing number of mold and die makers are considering automation to get better utilization of their equipment and skilled people. While it will take good planning and execution, there is a manageable path to automation that will bring efficiencies to tool shops in ways hardly imaginable only a few years ago.

Read MoreHurco to Host Job Shop Automation Webinar

Hurco will host a job shop automation webinar June 16 at 2:00 PM (EDT).

Read MoreStackTeck Introduces FastTrack Automation

StackTeck Systems Ltd. introduces its own brand of IML robots for all molds built within the FastTrack program.

Read MoreAutomation Technology Enables Flexible Capacity Adaptation

Grob Systems Inc.'s automation technology enables flexible adaptation to capacities and guarantees coordinated pallet handling.

Read More8 Mold Design Decisions That Impact Automation

Making the right decisions during eight key mold design phases will avoid automation problems and save money on price, installation and operation.

Read MoreShrink Fit System is Industry 4.0-Ready for Shop Floor Communication

Haimer’s power clamp comfort i4.0 shrink fit system sets new standards regarding digital connectivity and communication of tools and machines for manufacturing.

Read MoreSoftware Streamlines Design to Manufacturing Process

HCL Technologies releases CAMWorks ShopFloor, which provides tools for companies to meet smart manufacturing and Industry 4.0 initiatives by moving beyond 2D drawings or static digital files.

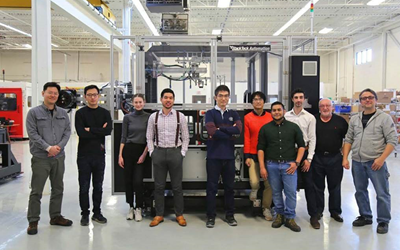

Read MoreTooling Tech Group Completes TTG Automation Expansion

Tooling Tech Group has announced that its TTG Automation facility in Temperance, Michigan, has completed a 14,000 sq. ft. expansion.

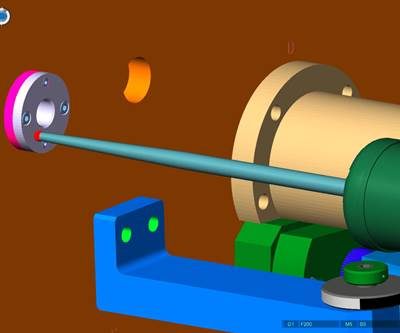

Read MoreSoftware Features Automation Functionality

The NCSIMUL machining module now includes automation functionality that provides wider control for jobs across various devices by communicating with distant servers.

Read Moree-Spindle Enables Full Participation in Smart Manufacturing

Absolute Machine Tools partner PCI SCEMM (a Tongtai company) introduces the e-Spindle, an electro-spindle that integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and workpiece quality.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)