e-Spindle Enables Full Participation in Smart Manufacturing

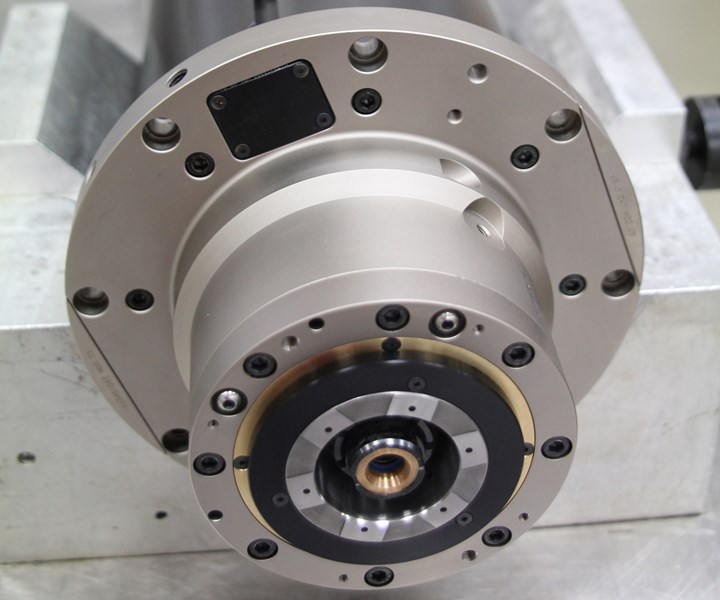

Absolute Machine Tools partner PCI SCEMM (a Tongtai company) introduces the e-Spindle, an electro-spindle that integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and workpiece quality.

Absolute Machine Tools partner PCI SCEMM (a Tongtai company) introduces the e-Spindle, an electro-spindle that integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and workpiece quality. The e-Spindle technology enables customers to fully participate in smart manufacturing.

The e-Spindle showcases smart machining technology with real-time monitoring of cutting process variables including force, vibration and coolant pressure. An adaptive drilling application illustrates the benefits of ongoing vibration control, and a honing toolholder operation features integrated measurement of workpiece diameter to permit continual control of abrasive honing tooling.

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

.jpg;maxWidth=300;quality=90)