Case Study

High-Performance Machine Improves Large Automotive Mold Machining

With a new generation of automotive mold applications ahead, the VG is ashowpiece that reflects Hi-Tech Mold's dedication to future innovation.

Read MoreSmall Shop HM CS Tool Engineering: The Business Of Customer Service

Despite its location in Cedar Springs, MI—a state that has been hard hit by the economic downturn—CS Tool Engineering, Inc. has landed the 2010 Leadtime Leader Award Small Shop Honorable Mention by constantly investing in technology and offering its customers complete customer service with leadtimes between 10 and 12 weeks.

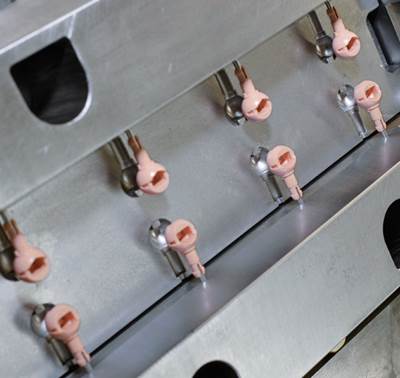

Read MoreFrom the Field: Programming Software for Producing Playmobile Toy Molds

If it is still the norm in many tool- and moldmaking businesses to carry out programming either offline or directly on the machine, then the Playmobil example shows that a combination of both provides a lot of scope for creating and implementing new ideas.

Read MoreSavings from the Front Lines: Rebuilding Saves Molders Money

This quarterly series features actual examples of a front-line mold building company presenting new approaches to improve the customer's profitability.

Read MoreNew Business Opportunities: New Equipment Investment Solidifies Medical Mold Prototyping Niche

Investing in an additional high-speed machining center and converting to electric presses rather than hydraulic has allowed mold manufacturer/molder Injection Mold, Inc. (North Vernon, IN) to step up its game by speeding up already quick delivery times.

Read MoreBerrien Tool Coalition: A Marketing Edge

This group of companies delivers a full-systems approach to manufacturing—art to part and every-thing in between.

Read MoreEarly Collaboration, Part Design Involvement Key to Global Growth in Packaging

This mold manufacturer has achieved success by partnering with manufacturers in the packaging and closure markets on innovative plastic part designs—not simply providing a mold quote.

Read MoreTooling Transfer: Sampling Success

Fifteen steps to facilitate a smooth tool transfer between the OEM, new molder and your shop.

Read MoreCutting Tool Slashes Cycle Times by 75 Percent

This moldmaker reduces cycle times from 10 hours to two hours with a more durable, faster cutter that also leaves a nice finish.

Read More

.jpg;maxWidth=300;quality=90)