Build

Big Daishowa Incentive Supports Manufacturing Training Programs

Through the end of the year, Big Daishowa will donate a tooling certificate valued at 20% of every order from an NTMA member company to the buyer’s school of choice.

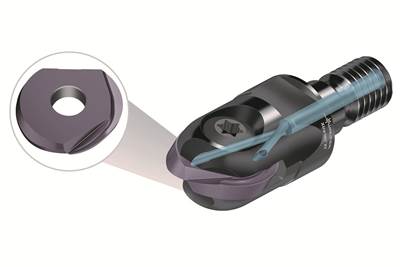

Read MoreProfile Milling Cutter Delivers Precision Machining, Optimized Tool Life for Molds

The new Walter USA Xtra·tec XT M5460 offers precise, cost-effective machining and optimize surface finishes for mold and die making, aerospace and energy industries.

Read MoreHardinge Receives Metalworking Reshoring Award

The National Metalworking Reshoring Award honors companies that have effectively reshored products, parts or tooling made primarily by metal forming, fabricating, casting or machining, including additive manufacturing.

Read MoreTwo Reasons to Form Additive Tooling Partnerships

Partnering with experienced 3D printing resources is essential to remaining competitive in today’s ever-evolving moldmaking industry.

Read MoreIntelligent CNC Surface Grinders Meet Mold and Die Market Demands

Developed for a variety of industries, Chevalier’s newly designed Smart-IV grinders with Smart iControl enhance machining intelligence, dynamics and affordability.

Read MoreWelding Repair Services for Additive Manufactured Molds

Precision Laser Technology relies on its experience and expertise in laser welding and tool metallurgy to ensure mold repair success, including a recent partnership with Mantle to to prove out AM technology.

Read MoreMolds, Hot Runner Systems, Digital Technologies Highlight Sustainable Production

The Molding Solutions network at K Show displays Männer, Foboha, Synventive, Thermoplay, Priamus, Gammaflux and other external partners and their new or proven technologies for molding and moldmaking.

Read MoreTechnology Roundup: The K Show Experience

Catch a glimpse into technologies for plastics, rubber, injection molding, hot runners, sustainability and more being showcased at this year’s K 2022.

WatchSubmicron-Grade Carbide End Mills Achieves Material Removal Versatility

Greenleaf Corp. introduces the high-performance Greenleaf-360 cutting tools combining strength, toughness and heat resistance for machining material capabilities in industries like medical and mold and die.

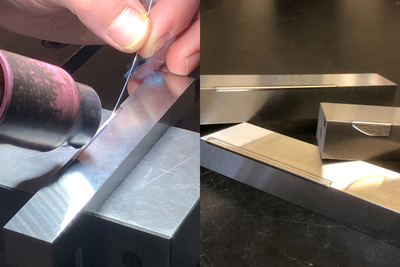

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)