Intelligent CNC Surface Grinders Meet Mold and Die Market Demands

Developed for a variety of industries, Chevalier’s newly designed Smart-IV grinders with Smart iControl enhance machining intelligence, dynamics and affordability.

Intelligent, dynamic and affordable are three words that are said to describe the driving forces behind Chevalier Machinery’s newly design Smart-IV Series of CNC surface grinders. They’re also the benchmarks required by the medical, energy, semiconductor, aerospace, mold and die, and processing industries to meet current and future market demands.

With six machine sizes available, this series is capable of producing complicated shapes along with finer finishes, resulting in highly accurate workpieces, according to the company. Heavy-duty slide rails, a one-piece base casting and hardened wheelhead guideways create a solid, rigid machine structure that minimizes vibration, movement and displacement. A fully enclosed cover design provides more protection to the operator, preventing cutting coolant splashing and oil mist dissipation while avoiding grinding danger.

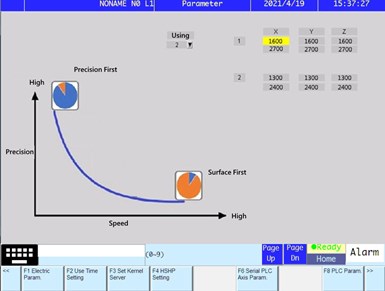

A next-generation SMART iControl incorporates additional production efficiency, Chevalier notes. An intelligent grinding assistant system sets parameters based on prioritizing the machining process for precision or speed in order to improve application efficiency. The SMART grinding path feature automatically minimizes air-cutting strokes during grinding of irregular shapes like I, L, Z or triangular. It also automatically removes invalid cutting strokes and improves overall processing efficiency up to 40%. A grind CAM built-in function enables users to import CAD files for wheel and part profiles, and convert file data to processing paths. Intelligent auto wheel dressing, in-machine dynamic balancing, a workable soothing function and TaskLink+ are additional features provided.

The Smart-IV Series also features tools to secure big data with Chevalier’s iMachine Communications System (iMCS). Combined with 24/7 data collection, utilization monitoring, data analysis, alarm history, maintenance and overall equipment effectiveness (OEE), this software package enhances machine efficiency in the factory while enabling remote monitoring and diagnostics to track machine performance and identify potential problems.

Related Content

-

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

.jpg;maxWidth=300;quality=90)