Automation

Using Digital Thermography in Mold Manufacture

Digital thermography is an effective tool for bringing solutions to your customers.

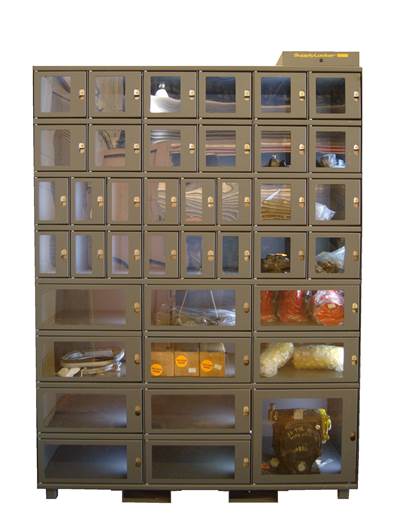

Read MoreAutomated Access to the Right Cutting Tools

An essential part of any automated moldmaking operation is being able to access the right cutting and maintenance tools.

Read MoreAutomation Investment Yields Speed and Flexibility

In 2004, Industrial Molds Group took the first steps toward integrating automation to reduce both costs and turnaround times.

Read MoreFrom the Editor: What Makes You Stand Out?

A winning business strategy, automation success, a dedicated, skilled workforce, controlled growth, leadtime tactics, the right technology investment, new market penetration, an effective marketing strategy?

Read MoreNew Dynamic Milling, Multiaxis Machining, Smart Hybrid Finishing

CNC Software announces the release of Mastercam X5.

Read MoreSustained Commitment to Automation Reaps Rewards

Through consistent automation strategies, one mold shop was able to implement new equipment and ramp up training, allowing them to accelerate out of tough times and be prepared for upcoming business opportunities.

Read More2010 Leadtime Leader Award Small Shop Winner Mold Craft, Inc.: Innovation with Automation

With an average leadtime of eight weeks, Mold Craft, Inc. (Willernie, MN)—this year’s Small Shop Leadtime Leader Award Winner—builds tight-tolerance, high-volume, multi-cavity and multi-mold projects that produce small, intricate, precision plastic parts.

Read MoreSmall Shop HM CS Tool Engineering: The Business Of Customer Service

Despite its location in Cedar Springs, MI—a state that has been hard hit by the economic downturn—CS Tool Engineering, Inc. has landed the 2010 Leadtime Leader Award Small Shop Honorable Mention by constantly investing in technology and offering its customers complete customer service with leadtimes between 10 and 12 weeks.

Read MoreAutomation: Where to Begin And End

How mold manufacturers are benefitting from today’s automation options.

Read More