Additive Manufacturing

Adapting to New Ways of Working During COVID-19

Mold material suppliers are in the fight against COVID-19 just like their mold-building customers, and learning similar lessons too such as the benefits of going paperless and working remotely.

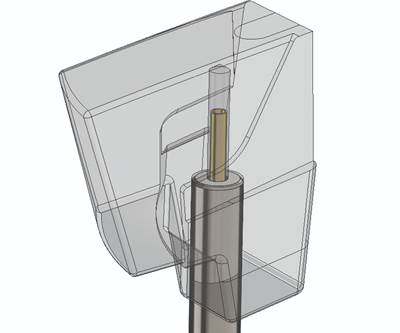

Read MoreHow to Use Additive Tooling in Difficult-to-Cool Areas of a Mold

Difficult-to-cool areas of a mold cost cycle time, making the perfect application for additive tooling, including retrofitting an existing tool with lifters, slides and high wear areas.

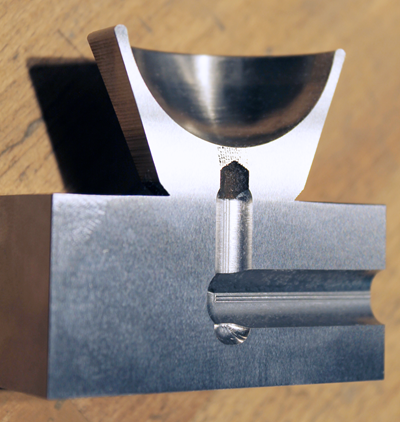

Read MoreHybrid Milling Machine Effectively Vents Gas

Matsuura Machinery USA Inc.’s Lumex technology makes effective mold/gas venting possible and improves the quality of molds.

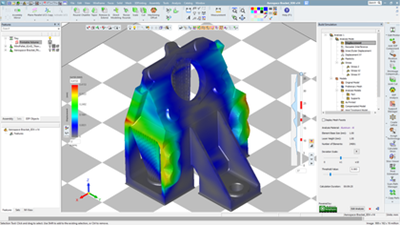

Read MoreFREE ON DEMAND WEBINAR: Reduce Delivery Time and Increase Mold Quality With The Right CAD/CAM Solution

Learn how a dedicated integrated CAD/CAM solution can enable mold builders to increase productivity and deliver high-quality tools of any complexity and size in record time.

Read MoreSoftware Add-On Streamlines Design for Additive Manufacturing Cycle

3D Systems launches its latest software solution 3DXpert for SolidWorks 15, which prepares and optimizes users’ designs for additive manufacturing.

Read MoreThe Cool Parts Show Finds Additive Manufacturing Advancing During Pandemic Crisis

The Cool Parts Show, the series from Additive Manufacturing Media about 3D printing for industrial production, has produced special episodes about 3D printing during the COVID-19 crisis.

Read MoreCommunity Addresses Coronavirus PPE Backlog with 3D Printing

As the COVID-19 crisis has deepened, Rocklin Manufacturing has been addressing the need to fulfill the growing PPE backlog by not only turning to 3D printing, but by also connecting with its local community.

Read MoreHow to Maintain Additive Tooling

Implementing additive tooling into a mold can be a daunting task, but maintaining it over the life of the tool can be straight-up scary. Here are three steps to include in your maintenance plan.

Read MoreDirect Rapid Soft Molds Open Up New Applications in Micro Injection Molding

Nanofabrica's Direct Rapid Soft Tooling (DRST) process enables lead times of two hours from file to injected part. With up to 1000 injection-molded parts per tool, the technology unlocks potential applications in small or medium-batch manufacturing.

Read MorePVD Coatings Solve Common 3D-Printed Mold and Part Problems

The right surface modification solution can alleviate a few common additive manufacturing pain points that typically require creating new molds or parts.

Read More

.jpg;maxWidth=300;quality=90)