Milling Machines Offer Enhanced Productivity

Dongguan Gooda Machinery offers the VM-1625, a high precision, double-column vertical milling machine designed to handle extreme milling conditions.

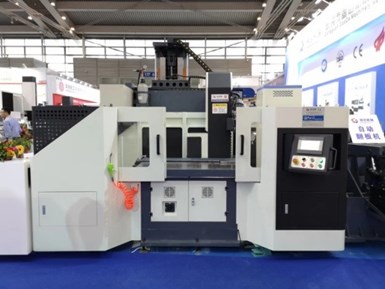

The VM-1625

Dongguan Gooda Machinery offers the VM-1625, a high precision, double-column vertical milling machine designed to handle extreme milling conditions. With a 6,000-pound casting, the VM-1625 delivers high-speed table stroking and thermally stabilized precision. The milling machine provides automatic measurement, tool-setting, tool division, connection cutting, and rough cutting and finish cutting. It can hold workpieces firmly, and contour workpieces can be filled arbitrarily in the range of worktable size for efficient performance. The close cover design saves space and opens the work area for easy access, significantly enhancing work safety and environmental performance.

The CNC Milling Machine TH-1200NC

The company also offers its CNC duplex sides milling machine, which delivers multi-functional cutting, including chamfering. Outside milling is possible with a 45/135-degree chamfering type with square insert point. It offers a family of high-speed, high-accuracy milling machines designed as CNC duplex milling machine with chamfering function. The milling machine can come with a FANUC system, which simultaneously mills two sides, and is also available with a Siemens or Mitsubishi system. Roughing stock is removed by high-speed feed and precision details are ground in finish cycles.

The Double Heads Vertical Milling Machine_VM-1130NC

The company’s automatic five-axis CNC chamfering machine reduces operations on other work centers and eliminates variability of hand beveling machines. Its high-speed back chamfering capability reduces hand deburring. The C-Cutter is available in new inserts or the insert used by mill designs. It uses the insert four edges while mill uses its insert point. The machine is suitable for mold base applications, mold frames, metal component including aluminum mold and copper alloys, manifolds block and hydraulic valve blocks. It is available in flats, squares and standard forms.

Related Content

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.